The unit is a laser-based inspection system that detects pressure inconsistencies in glass and can containers.

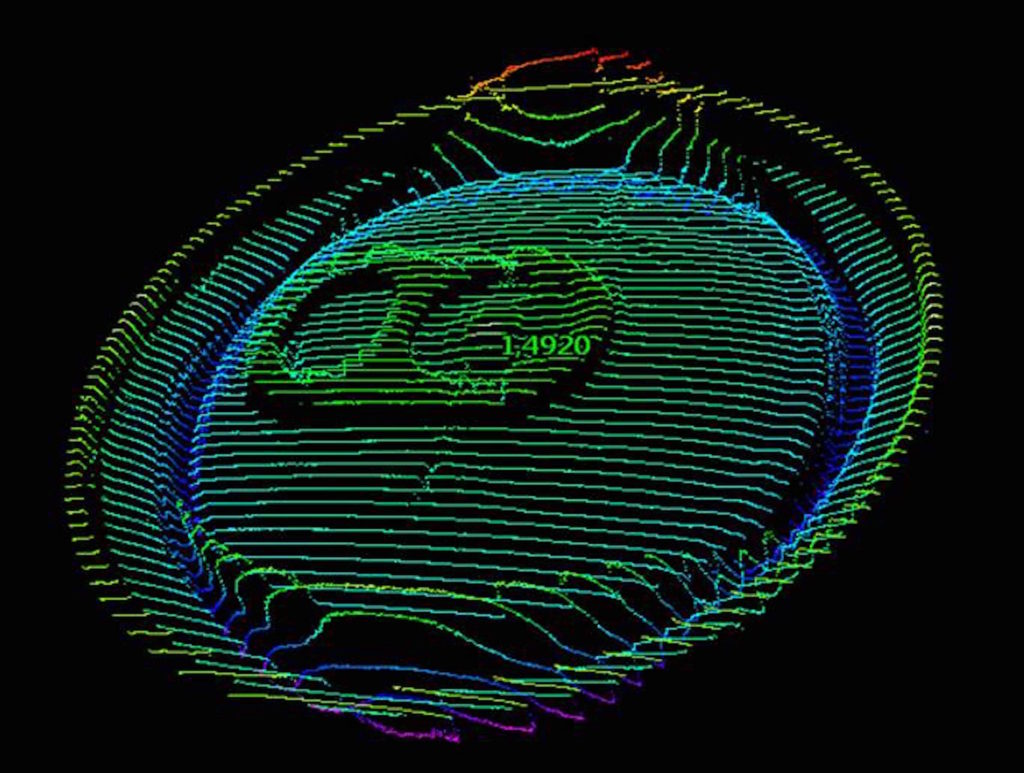

It uses multi-point laser scanning technology to generate 3D maps of container surfaces, detecting pressure variations with extremely high accuracy.

According to the manufacturer, AURAtec accurately performs with nearly a six sigma margin detecting acceptable vs unacceptable common aluminium beverage cans.

“Beneath its compact profile, the AURAtec packs the powerful punch of a high intelligence machine,” explained Leon Coetzee, vice president of product marketing at FILTEC.

He added: “The AURAtec stands out for its ability to produce powerful 3D assessments of the container’s pressure profile, at inspection speeds exceeding 1200 containers per minute.

“The system is not affected by container positioning variances on the X, Y, or Z axis, thus being very tolerant to normal production line conditions.

“The AURAtec obsoletes traditional analogue or acoustic based technologies, replacing them with an ultrahigh resolution 3D vision solution that also excels in robustness and longevity.”

Available for delivery in the fourth quarter of this year. AURAtec’s advanced pressure detection system can be utilised as as a stand alone inspection unit or integrated with existing FILTEC products.