Other than sugar, nitrogen is probably the most important macronutrient required for yeast health and growth. Nitrogen deficiency is associated with several fermentation difficulties including stuck and incomplete fermentations, whereas excess nitrogen is related to the production of both off flavours and beer spoilage.

Nitrogen is often assessed by measuring Free Amino Nitrogen (FAN) or to give it its other name Primary Amino Nitrogen (PAN). FAN or PAN assays, test for the concentration of amino acids and small peptides that are utilized by yeast for cell growth and proliferation. Together with ammonia, FAN/PAN makes up what is known as Yeast Assimilable Nitrogen or YAN.

FAN compounds are formed naturally during malting and mashing by the action of protein degradation enzymes on hordein, a protein found in the grain. The level of amino acids available in the wort relies on several variables including grain variety, as well as malting and mashing conditions, but the overall types of amino acids available will be similar among all whole malt worts. Likewise the specific amino acids taken up by yeast follow a similar pattern during fermentation, although environmental changes can alter this.

Using adjuncts, such as corn and rice, dilute FAN levels in the wort while increasing fermentable sugars. Consequently, high-adjunct worts are nitrogen deficient and fermentation can be adversely affected, leaving high levels of sugars in the beer. FAN levels in the wort are often regarded as the best indicator of potential yeast growth and are therefore directly related to fermentation efficiency. Yeast need FAN to grow and reproduce, so theoretically the more you have the quicker your yeast will grow, the stronger it will be and the more alcohol your yeast will produce.

Yeast consume most of the FAN in the first 36-40 hours of fermentation, during its propagation phase. As they do so they can produce a range of metabolic by-products some of which affect flavour and stability of the finished beer.

Studies appear to have resulted a general belief that a minimum level of 150 mg/L FAN is required for complete fermentation, with 200-250 mg/L being seen as ideal. However more recent data suggest wort FAN levels might need to be higher, especially in some higher ABV beers. Work published by Stone Brewing found that on average IPA samples tested had levels of approximately 250 mg/L in the wort and 133 mg/L in the pre-filtered beer samples. In contrast, the higher gravity double IPAs had even higher wort and pre-filtered FAN levels, 316 mg/L and 175 mg/L, respectively.

Craft breweries (due to their use of all malt wort) have the opposite problem to macrobreweries, and need to monitor excess FAN levels to control haze and the production of off flavours, such as diacetyl, or higher alcohols like isoamyl alcohol, propanol, and isobutanol— all of which cause alcohol heat in your finished product. While excessive FAN levels produce a perfect growth environment for spoilage organisms.

The traditional way to determine protein content in a beers was the Kjeldahl method, however it was both complex and expensive as such it has more or less been replaced by the ninhydrin method. The ninhydrin method estimates amino acids, ammonia, and the terminal nitrogen groups of peptides and proteins (YAN) and is listed by the European Brewery Convention (EBC), MEBAK, and American Society of Brewing Chemists (ASBC) as the method of choice for FAN measurement. However although an improvement on the older method, its still quite time consuming and there are a lot of reagents to buy.

Apart from the spectrophotometer you would also need a hot water bath and a range of different reagents, in addition to this the assay itself takes about an hour to do from start to finish. An overview of the basic procedure is given below.

Preparation of Reagents

A. Ninhydrin Colour Reagent:

Dissolve 10 g Na2HPO4, 6 g KH2PO4, 0.5 g ninhydrin and 0.3 g fructose in a total of 100 mL of distilled water.

B. Dilution Solution:

Dissolve 2 g potassium iodide in 600 mL distilled water and then add 400 mL of 96 % ethanol.

C1. Glycine Stock Solution:

Dissolve 107.2 mg glycine in a total of 100 mL of distilled water.

C2. Glycine Standard Solution (working solution):

Dilute 1 mL of the glycine standard stock in 99 mL of distilled water. This standard solution contains 2 mg/L amino nitrogen.

Assay Protocol

1. Dilute 1 mL of beer in 49 mL (or 1 mL of wort in 99 mL) in distilled water. Use 50 mL distilled water for a blank.

2. Perform analysis of the sample, standard solution and H2O (blank value) in triplicates.

3. Pipette 2 mL of the diluted sample, the standard solution and blank solution into separate test tubes.

4. Add 1 mL of Ninhydrin Colour Reagent and mix.

5. Close each test tube loosely in order to avoid evaporative losses and heat the solutions at 100C for 16 minutes.

6. Cool the solutions at 20C for 20 minutes.

7. Add 5 mL of Dilution Solution and measure the absorbance within 30 minutes in a 10 mm cuvette at 570 nm against distilled water.

8. Read all of the blanks, standard and test samples on the spectrophotometer at 570nm

After all that there is a nice calculation to have a go at.

However if your not really bothered about using ‘approved methods’ and all you want is a FAN level then there is another much easier way.

The ninhydrin method measures YAN, but its time consuming and quite complex, especially if you don’t have a scientific background. However evidence suggests that a newer method called NOPA (alpha-amino nitrogen by OPA) gives almost the same result (99%), this method is quick and is available as a premade kit, in addition to that its also pretty cheap (£99.77/100 tests).

The kit I looked at is available from Megazyme (Ireland), the benefit of this kit, is that the reagents are stable, there is an easy method to follow and the website includes both a spread-sheet to automate the calculation and a YouTube ‘how to’ video.

The reagents used are:

Bottle 1 (Soln. 1): Tablets (100) containing N-acetyl-L-cysteine (NAC). Stable for > 2 years at 4°C or -20°C.

Bottle 2 (Soln. 2): Ortho-phthaldialdehyde (OPA) in 12 mL of ethanol (96% v/v). Stable for > 2 years at 4°C.

Bottle 3: Isoleucine standard solution (5 mL, 140 mg of nitrogen/L). Stable for > 2 years at 4°C.

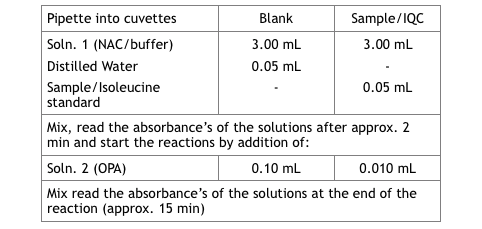

Process:

Dissolve one tablet from Bottle 1 in 3 mL of distilled water for each assay planned and allow to dissolve over 2-3 min. Aid dissolution by shaking, stirring or crushing with a metal spatula. This is Solution 1. Prepare immediately prior to use.

Use the contents of bottle 2 as supplied, this is Solution 2. This solution is stable for > 2 years when stored in the dark at 4°C.

Use the contents of bottle 3 as supplied, this is the Internal Quality Control (IQC) and can be used as a check sample to ensure you have performed the assay correctly. Stable for > 2 years at 4°C.

Beer Metrics

Performing a pH is probably the easiest test you can do and once you have bought the pH meter its more or less free. In the last publication I also showed you how to perform IBU and EBC for less than £1. Both of these last 2 parameters require a spectrophotometer and although this bit of kit isn’t cheap (approx. 5K), you will get a quick return on your investment, especially if you currently use a contract lab for your chemistry.

If you don’t use a lab at all the saving will come from managing raw material usage and preventing wastage, for instance setting and maintaining an IBU level will prevent the overuse of hops, in addition your batch to batch consistency will improve and you will have a range of essential metrics to maintain your beers quality.

FAN measurement on its own it’s a ‘blunt instrument’, but if its used the other measurements mentioned, such as pH, IBU, EBC, ABV and microbiology screening it can provide the brewer with a valuable insight into the quality and consistency of their product. Allowing the brewer to monitor the quality of their raw ingredients, yeast health and efficiency, shelf life and beer spoilage potential.