The Czech Mini Breweries is the consortium of Czech manufacturers of small breweries, cider houses and equipment for production of beer and cider.

Its main mission is to spread the reputation of high quality Czech beer and Czech breweries all over the world. Its design and production team offers construction and modernization of breweries and microbreweries.

In this piece, it outlines the key features and benefits of seven products and systems it has on offer for small breweries.

1st solution: BREWORX VARIO CCT

Reduction of beer losses, energy costs, cost of sanitizing solutions and labour costs during the fermentation process of beer in cylindrical-conical beer fermenters.

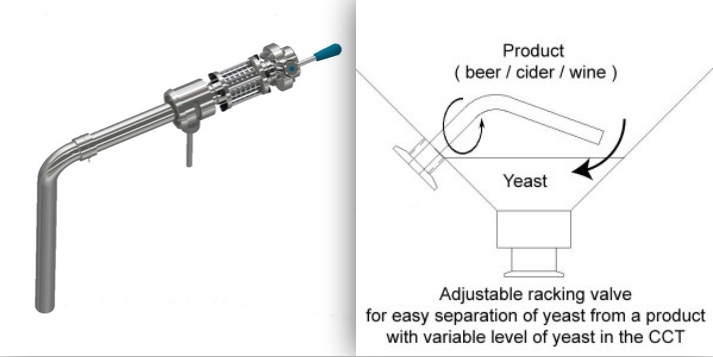

We recommend to use our new adjustable racking valve system for easy separation of yeast from the product (beer, cider, wine …) in fermentation and maturation tanks without loss of product residues. This system allows the precise height setting of the outlet pipe suction hole just above the actual level of yeast in the tank.

2nd solution: FERMENTATION-MATURATION UNITS

Fermentation and maturation unit FUIC is the equipment for fermentation and maturation of beer wort. During the fermentation and maturation of a wort produced in a brewhouse the wort becomes the final drink – beer.

Time parameters of the fermentation and maturation process depend on the type of beer, the set pressure in the cylindrical-conical tanks and the brewer’s requirements.

Here is a video presentation of this product : https://youtu.be/Pg3Wlsx9VFY

3rd solution: BREWORX MOBILE CIP

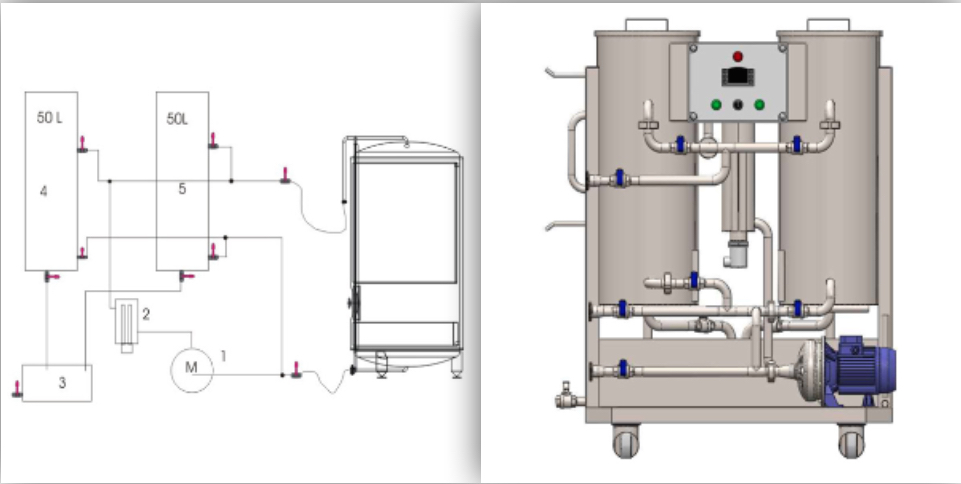

A convenient cleaning and sanitation of all tanks, vessels and pipes in your microbrewery – simple mobile CIP station.

Its function is based on a circulation of an alkaline or acid solution through a sanitary shower spraying it into vessel. It is also equipped with a flowheater with digital regulation of temperatures ranging from 0°C to 80°C.

CIP consists of two main tanks for alkaline and acid solution and one vessel for neutralizing of used solutions. The circulation of the sanitizing solutions is provided by a pump and system of connecting hoses.

The equipment CIP 50 is installed in a rigid frame provided with lockable travel wheels. Used material is stainless steel 1.4301 (AISI 304).

4th solution: BREWORX KEG WASHFILL

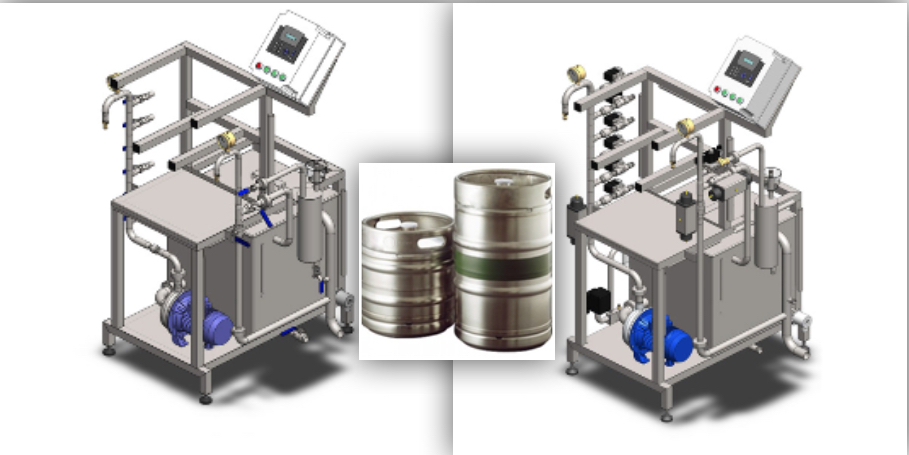

Cleaning and filling of beer kegs using the manual or automatic keg washing & filling machine or tools.

KCM-10 is designed for cleaning and filling 15-50 litres kegs. The working performance is 10 kegs (50 litres) per hour for sanitation and 7 kegs (50 litres) per hour for sanitizing and filling.

KCA-25 is designed for cleaning and filling 15-50 litres kegs. The working performance is from 8 to 25 kegs (50 litres) per hour. The device is controlled by a PLC where it is possible to change the time of each cycle.

Both keg washers are made of stainless steel. Inserting and removing of kegs is done manually.

5th solution: MODULO MICROBREWERY KIT

Build your professional microbrewery by yourself within one day! No projection work, object reconstruction work, expensive costs of installation by team of specialists.

BREWORX MODULO microbreweries are produced using modern methods from quality food steel exclusively of European origin. They enable the manufacture of traditional Czech beer, but also any other kind of beer using the decoction or infusion method.

You can produce light beer, half-dark, dark, stout type beer, ale, pale ale, white beer and many other beers by Czech and foreign recipes.

The design also allows the production of bottom and top fermented beers by a modern way of fermentation and maturation in special sealed FUIC units – cylindrical-conical tanks with independent coolers.

6th solution: BREWORX BEERCIDERLINE

Extend the ability of your brewery a cider manufacturing. This small investment will enable a professional production of beverage which is now conquering the world.

Production equipment for the production of cider is very similar to the brewery equipment. Instead of a hot block with a brewhouse it contains an assembly of machines for cleaning, crushing and pressing the fruit. The liquid intermediate which subsequently passes through a fermentation process is the fruit juice pressed from fruit.

Fermentation and maturation process takes place in cylindrical tanks that compared to tanks for beer production are slightly differently equipped. Fermentation takes place at higher temperatures and in addition to the cooling a device for heating of containers is needed to maintain the required fermentation temperature.

Our experience in the production of microbreweries ensures the superior quality of craftsmanship of the technology for the cider production. The production line includes several complete technologies for the cider production in a professional way.

7th solution: Complete beer fermentation & maturation sets

This set includes all necessary equipment for professional fermentation and maturation process. This set is also designed for production of cider from fruit or carbonated wine.

Assembling of the set is very easy. The installation does not require any professional workers – only adequate handling equipment for moving and installation of heavy containers (cylindrical-conical fermenters) on place after delivering of the set is needed.

All wires, temperature measuring and a regulatory equipment (excluding covered central control cabinet and cooler) operate with safety voltage 24V and can be installed by customer using the installation manual. Therefore the price of the set does not include the installation work.

About the Czech Mini Breweries consortium

The Czech Mini Breweries is the consortium of Czech manufacturers of small breweries, cider houses and equipment for production of beer and cider. Main mission is to spread the reputation of high quality Czech beer and Czech breweries all over the world. Our design and production team offers construction and modernization of breweries and microbreweries.

We also produce special stainless steel vessels (pressure tanks, jacketed refrigerated containers, vessels with agitators, containers for yeast growing, etc.) and we offer also design works, brewmaster services and consultation for beer and cider producers.

The breweries and brewing equipment manufactured by Czech Mini Breweries consortium are installed in Czech republic, Russia, Sweden, Netherlands, Norway, Ireland, Great Britain, France, Finland, Korea, Japan, Malaysia, Belgium, China.

More about us and our full offering:

http://www.czechminibreweries.com, http://eshop.czechminibreweries.com

Improvements for your Craft brewery from the Czech Republic

The Czech Mini Breweries is the consortium of Czech manufacturers of small breweries, cider houses and equipment for production of beer and cider.

Its main mission is to spread the reputation of high quality Czech beer and Czech breweries all over the world. Its design and production team offers construction and modernization of breweries and microbreweries.

In this piece, it outlines the key features and benefits of seven products and systems it has on offer for small breweries.

1st solution: BREWORX VARIO CCT

Reduction of beer losses, energy costs, cost of sanitizing solutions and labour costs during the fermentation process of beer in cylindrical-conical beer fermenters.

We recommend to use our new adjustable racking valve system for easy separation of yeast from the product (beer, cider, wine …) in fermentation and maturation tanks without loss of product residues. This system allows the precise height setting of the outlet pipe suction hole just above the actual level of yeast in the tank.

2nd solution: FERMENTATION-MATURATION UNITS

Fermentation and maturation unit FUIC is the equipment for fermentation and maturation of beer wort. During the fermentation and maturation of a wort produced in a brewhouse the wort becomes the final drink – beer.

Time parameters of the fermentation and maturation process depend on the type of beer, the set pressure in the cylindrical-conical tanks and the brewer’s requirements.

Here is a video presentation of this product : https://youtu.be/Pg3Wlsx9VFY

3rd solution: BREWORX MOBILE CIP

A convenient cleaning and sanitation of all tanks, vessels and pipes in your microbrewery – simple mobile CIP station.

Its function is based on a circulation of an alkaline or acid solution through a sanitary shower spraying it into vessel. It is also equipped with a flowheater with digital regulation of temperatures ranging from 0°C to 80°C.

CIP consists of two main tanks for alkaline and acid solution and one vessel for neutralizing of used solutions. The circulation of the sanitizing solutions is provided by a pump and system of connecting hoses.

The equipment CIP 50 is installed in a rigid frame provided with lockable travel wheels. Used material is stainless steel 1.4301 (AISI 304).

4th solution: BREWORX KEG WASHFILL

Cleaning and filling of beer kegs using the manual or automatic keg washing & filling machine or tools.

KCM-10 is designed for cleaning and filling 15-50 litres kegs. The working performance is 10 kegs (50 litres) per hour for sanitation and 7 kegs (50 litres) per hour for sanitizing and filling.

KCA-25 is designed for cleaning and filling 15-50 litres kegs. The working performance is from 8 to 25 kegs (50 litres) per hour. The device is controlled by a PLC where it is possible to change the time of each cycle.

Both keg washers are made of stainless steel. Inserting and removing of kegs is done manually.

5th solution: MODULO MICROBREWERY KIT

Build your professional microbrewery by yourself within one day! No projection work, object reconstruction work, expensive costs of installation by team of specialists.

BREWORX MODULO microbreweries are produced using modern methods from quality food steel exclusively of European origin. They enable the manufacture of traditional Czech beer, but also any other kind of beer using the decoction or infusion method.

You can produce light beer, half-dark, dark, stout type beer, ale, pale ale, white beer and many other beers by Czech and foreign recipes.

The design also allows the production of bottom and top fermented beers by a modern way of fermentation and maturation in special sealed FUIC units – cylindrical-conical tanks with independent coolers.

6th solution: BREWORX BEERCIDERLINE

Extend the ability of your brewery a cider manufacturing. This small investment will enable a professional production of beverage which is now conquering the world.

Production equipment for the production of cider is very similar to the brewery equipment. Instead of a hot block with a brewhouse it contains an assembly of machines for cleaning, crushing and pressing the fruit. The liquid intermediate which subsequently passes through a fermentation process is the fruit juice pressed from fruit.

Fermentation and maturation process takes place in cylindrical tanks that compared to tanks for beer production are slightly differently equipped. Fermentation takes place at higher temperatures and in addition to the cooling a device for heating of containers is needed to maintain the required fermentation temperature.

Our experience in the production of microbreweries ensures the superior quality of craftsmanship of the technology for the cider production. The production line includes several complete technologies for the cider production in a professional way.

7th solution: Complete beer fermentation & maturation sets

This set includes all necessary equipment for professional fermentation and maturation process. This set is also designed for production of cider from fruit or carbonated wine.

Assembling of the set is very easy. The installation does not require any professional workers – only adequate handling equipment for moving and installation of heavy containers (cylindrical-conical fermenters) on place after delivering of the set is needed.

All wires, temperature measuring and a regulatory equipment (excluding covered central control cabinet and cooler) operate with safety voltage 24V and can be installed by customer using the installation manual. Therefore the price of the set does not include the installation work.

About the Czech Mini Breweries consortium

The Czech Mini Breweries is the consortium of Czech manufacturers of small breweries, cider houses and equipment for production of beer and cider. Main mission is to spread the reputation of high quality Czech beer and Czech breweries all over the world. Our design and production team offers construction and modernization of breweries and microbreweries.

We also produce special stainless steel vessels (pressure tanks, jacketed refrigerated containers, vessels with agitators, containers for yeast growing, etc.) and we offer also design works, brewmaster services and consultation for beer and cider producers.

The breweries and brewing equipment manufactured by Czech Mini Breweries consortium are installed in Czech republic, Russia, Sweden, Netherlands, Norway, Ireland, Great Britain, France, Finland, Korea, Japan, Malaysia, Belgium, China.

More about us and our full offering:

http://www.czechminibreweries.com, http://eshop.czechminibreweries.com

ARTICLES

Sustainability | It’s time for change

Packaging | Crown caps and their role in your beer

Brewer’s Spent Yeast Market Projected to Reach $2.17 billion by 2030 – new research

Big Drop extends AF draught choice

PODCASTS