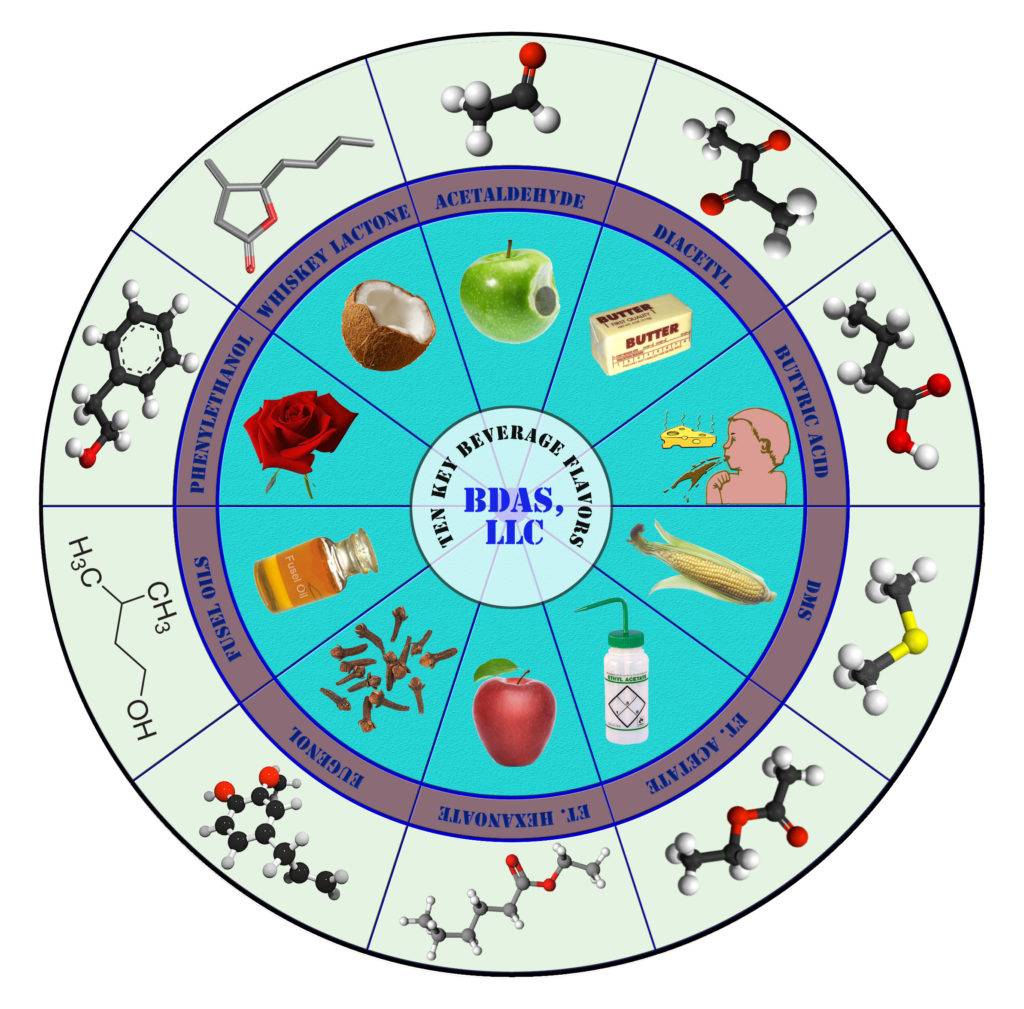

An understanding of a couple of dozen or so compounds from their aroma and taste can go a long way to ensuring the quality of the final product. Sensory evaluation provides an inexpensive quality control program for every beverage manufacturer and starts with tasting the brewing liquor, the raw materials and all steps along the way.

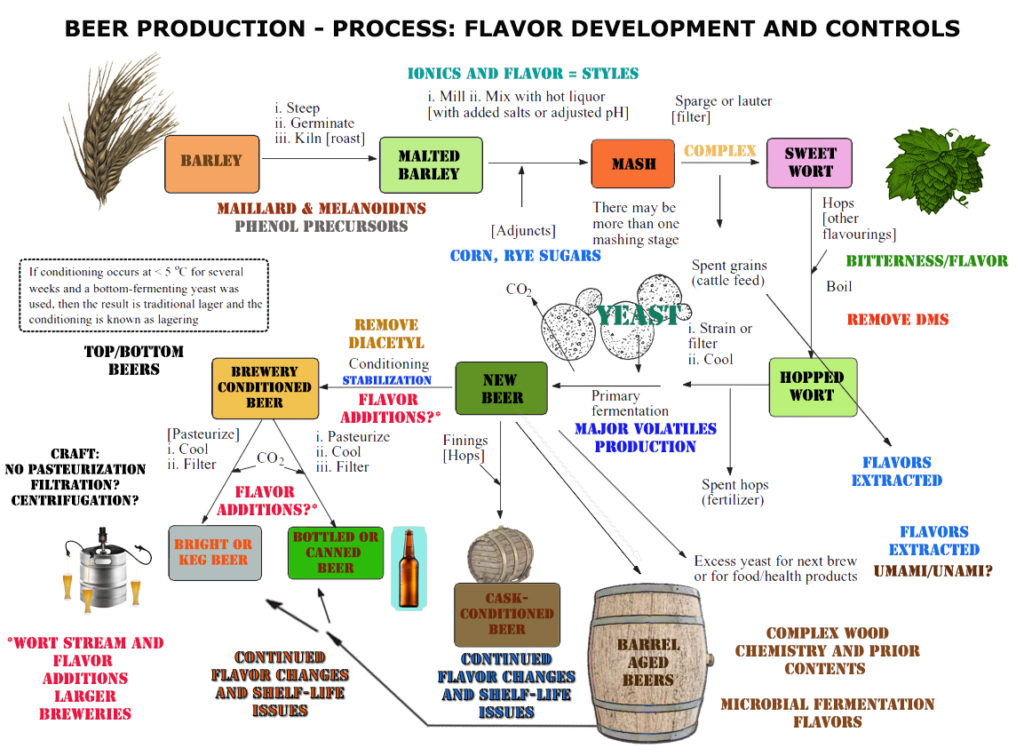

Each step in brewing (see schematic in Figure 1) provides points of entry or control of flavour components which impact final product. The raw materials can be discussed another time but malt and hop specification sheets should be consulted to appreciate the flavour notes that will be imparted to the beer through their judicious use.

These ingredients must be inspected visually, aromatically and through the preparation of small-scale malt “teas” and hop “teas” preparations and tastings. If force carbonating the beer – test the flavour and aroma of the commercial CO2 source by bubbling some through water and sniffing and tasting to ensure no major issues such as strong corn aroma (dimethyl sulfide or DMS-like) or hydrogen sulfide (rotten eggs) exist. From malt: grainy, cereal, toffee, chocolate, coffee and more subtle roasted and phenolic notes. Hops: citrus, fruity, piney, floral, herbal and much more.

Next in this brief journey, and assuming quality yeast is used (for traditional beers), a clean fermentation provides the main soup of aromatic volatile components found in beer.