The vast majority of beers around the world are made from three natural ingredients – water, malted barley, and hops. Together with yeast these ingredients are used in a centuries-old brewing process, to create high-quality beer.

Although wheat, rye, oats, millet, sorghum, rice and corn have all been used for brewing, barley is the preferred grain for beer. Malted barley gives beer its colour, malty sweet flavour, dextrins to give the beer body, protein to form a good head, and perhaps most importantly, the natural sugars needed for fermentation. The provisional barley production figure for the UK alone increased by 10.6% to 7.4 million tonnes in 2017 (1).

Once the barley has been sourced, it is then taken to the malting lines to be processed to malt. Malted barley is the source of the sugars (principally maltose) which are fermented into beer. The malting process allows the grain to partially germinate, making the seed’s resources available to the brewer.

The malting process from barley to malt is completed in one week. Once tested and approved the malt is then exported breweries, where the malted barley can be fermented into beer.

The need for testing

One challenge brewing laboratories are faced with is the risk of the production of NDMA during the malting process. NDMA is a potentially dangerous compound which is formed in malt when nitrogen oxide from pollution in the air reacts with certain amines in germinated barley when it is kilned. High levels of NDMA can pose a number of risks to human health including, liver damage. NDMA is, therefore, now part of the malt specification for many brewing labs, meaning it is compulsory to test malt for any remnant of the harmful chemical.

Malting operations fully meeting the requirements of this specification will be able to demonstrate to customers and other interested parties that best practice in malting operations have been followed and food safety and quality hazards are effectively controlled.

The use of a Gas Chromatography (GC) in combination with the Thermal Energy Analyser (TEA) detector is commonly used for the determination of NDMA.

Large breweries have long used GC for quality control and quality assurance, but it has not been financially viable for craft breweries, until recently due to easy-to-use and affordable equipment.

The malting process

Stage 1: The first step is steeping, where the barley is submerged in water for up to two hours in order to increase its moisture content. During this process the natural germination process of barley kernels will commence.

Stage 2: The steeped barley is then transferred to a germination room, where more moisture is added and ventilation takes place to allow the kernels to germinate properly. The germination process takes around five days and within this time the necessary enzymes are formed that the brewery will need to produce the beer. To prevent production loss the process must be stopped, and the third phase commences.

Stage 3: This final step is called the kilning phase. A kiln, described as a big drying oven, dries the germinated barley from a moisture content of around 45% to a moisture content of about 4.5%. At this rate a microbiologically stable product is formed with characteristics of pale malt that is advantageous for use.

The testing process

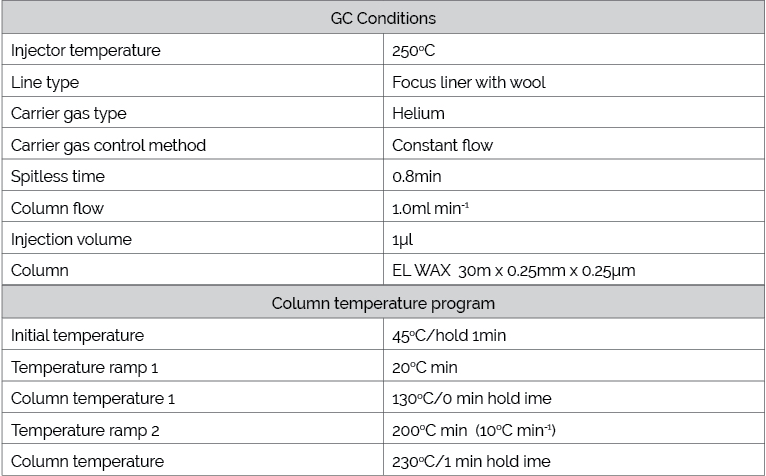

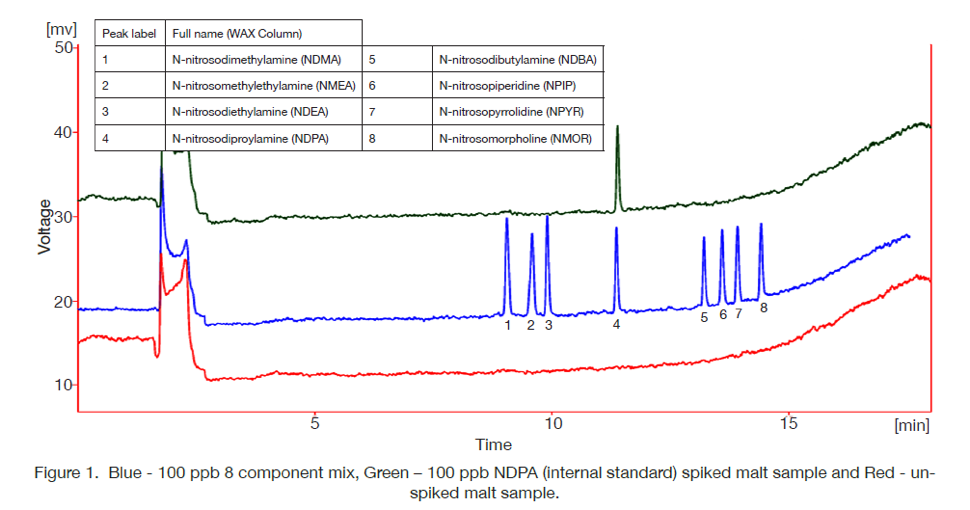

Samples are taken from production batches and are tested for the presence of NDMA. The malt sample, in figure 1, showed no observable response for NDMA or any other nitrosamines. The 200 Series Gas Chromatograph (Ellutia) with an EL-WAX column was utilised alongside the 800 series TEA (Ellutia). GC conditions are included in Table 1.

Samples were extracted in duplicate. Each replicate had 50 grams of malt ground up and had 100 ml deionised water added.

The extract was filtered through a Whatman Grade 1 filter paper and 1 ml of 10 ppm NDPA (n-nitroso di propylamine) internal standard was added to one extract (this generates a 100 ppb NDPA spiked sample). The samples were then made up to 100 ml with deionized water volumetrically.

To a vial, 10 ml of extract, 3 grams of sodium chloride and 10 ml of dichloromethane (DCM) was added and shaken for 5 minutes. Then the layers were left to separate for 15 minutes. The lower layer containing DCM was pipetted out into a clean vessel. 10 ml of DCM was added to the extract and the liquid/liquid extraction step was repeated. After this step, the DCM (final volume approx. 20 ml) was dried using 1 gram of sodium sulphate and then pre-concentrated to 1 ml under a nitrogen flow of approx.1 l min-1. A 1 μl injection of the concentrated DCM was directly analysed.

The identity of the internal standard was confirmed against the 8 component nitrosamine mix standard. This shows that the NDPA internal standard used has the same retention time as the NDPA contained within the standard (figure 1).

The peak areas for the spiked sample compared with the standard for NDPA showed good correlation, indicating a good recovery of the internal standard, and thusly, indicating very limited losses of any potential nitrosamines from within the sample during the preparation steps. The unspiked sample showed no peaks within the retention times of any of the nitrosamines in this standard mix.

TEA Technology

The TEA has been an industry standard for nitrosamine analysis since its introduction, thanks to its incredible sensitivity and almost infinite selectivity for nitrogen containing compounds. Within the brewing sector, complex mixes of compounds uniquely characterise each alcoholic beverage, creating the individual aromas and flavours consumers enjoy.

Whilst the majority of added compounds enhance the desired aroma and flavour aspects of a beverage, trace components can contribute off-flavours and odours, such as nitrosamines within the kilning process.

TEA detectors are used widely in the brewing industry, particularly since the craft brewing sector has been experiencing significant growth due to soaring consumer demand around the world.

Andrew James is Marketing Director at Ellutia. Andrew has worked at Ellutia for over 20 years, during this time he has been involved with many aspects of the business from product development to strategic planning.

This wide range involvement has developed an extensive wealth of knowledge and experience in the chromatography industry.

References

Department for Environment Food & Rural Affairs, 2017. Farming Statistics – First estimates of 2017 UK wheat and barley production.

(Internet) https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/649531/structure_jun17_wheatandbarleyUK_05oct17.pdf [Accessed 21/01/2019]