There are a number of ways we can turn the temperature down on rising costs. Filtration technology and expertise can help breweries become more efficient, explains Mark Richardson, processing product manager at Parker Bioscience Filtration.

Rising energy costs, according to a report by Frontier Economics for the British Beer and Pub Association (BBPA), are the biggest threat to breweries’ viability. Add to that increased raw material prices and breweries are under increasing pressure to operate more efficiently.

Clearly there are no easy fixes to the threats posed by energy price rises or supply chain disruption.

But by addressing how beer is stabilised and how filtration systems are operated, significant savings are possible.

Flash pasteurisation. This is where beer is pasteurised for a short time at typically 70°C – is a common method of removing spoilage microorganisms.

However, a large amount of energy is required to achieve the temperatures required for the process to run effectively.

There are additional costs, too. Heating the beer will cause the CO2 to come out of solution unless the line pressure is increased and tightly controlled.

This means that booster pumps which regulate the line pressure at approximately 10–14barg are necessary to control degassing. Running these pumps requires a significant amount of electricity.

Cold stabilisation. This is the use of filtration to achieve microbially stable beer – uses less energy and is more environmentally friendly.

Heating the beer isn’t required and as long as the line pressure is maintained at approximately 1barg, there is also no requirement to run booster pumps.

Cold stabilisation also enables breweries to reduce water use and beer losses. Flash pasteurisers work by passing the beer through a plate heat exchanger (PHE) at a required flow rate.

Above: A cold stablisation module using Parker’s Prepor NG and Bevpor BR filters at Zagrebačka pivovara in Croatia.

The Pasteurisation Unit (PU) level is a function of temperature and time – which means that flowrate through the system is critical. The correct pressure also needs to be maintained to achieve the correct carbonation level and prevent degassing as the beer heats up.

If these parameters fluctuate and cause the PU level to change, the process will be stopped and held in standby mode – which typically involves dumping the beer.

The beer is replaced with an equal quantity of flowing water until the problem is rectified… and this can result in huge quantities of water being used.

Cold stabilisation is a far less volatile method, as there is not such a high demand on a reliable flow rate, temperature, or pressure.

The water consumption of a cold filtration system, therefore, can be much smaller than that of a pasteurisation system.

In addition, in the pasteurisation process, every time there is a batch change, the water consumption far outweighs that associated with cold stabilisation.

Ensuring that filters last longer before they need to be replaced, and reducing blockage rates, can have an impact on both consumable spend and a brewery’s productivity.

The more frequently filters need to be switched out, the more often a process will need to be put on hold. And the faster filters come to the end of their usable lives, the greater the expenditure on replacements.

Developments in membrane filtration technology have helped to address these challenges. Parker’s Bevpor BR filters, for example, feature unique, graded density PES membranes which have been engineered to resist blockages by capturing microbial contaminants without restricting flow paths.

They have been developed to return the maximum lifetime and throughput to blockage, helping to reduce the operational costs of microbial stabilisation.

The optimisation of filter systems is also key. Ensuring the correct pre-filtration measures are in place, that filters are sized correctly and that they are suitable for filtering the specific product required, are all vital considerations.

Filters themselves certainly shouldn’t always get the blame for blockages. A change in process fluid (for instance water from a new municipal source) can cause filters to block more frequently if the system hasn’t been correctly optimised.

Filtering a new beer product with the same system as used on a different product can again, cause premature blocking – for example, if the ‘new’ product has an elevated protein content.

Specialist expertise is required to ensure optimisation is successful: Parker’s Technical Support Group, for instance, can undertake filterability trials to optimise filtration, analyse blocked cartridges, and conduct process analysis to support brewers.

Of course, an effective Clean in Place(CIP) regime will remove and/or reduce blockage components to prolong a filter’s lifespan. Filters should be cleaned regularly to control microbial levels and they should be cleaned between product batches to prevent cross contamination. CIP will also support the sanitisation of filters by removing and/or reducing retained microorganisms to prevent microbial build-up.

Techniques for CIP include using hot water, employing a caustic wash or a peracetic acid (PAA) wash, using disinfectant or backwashing with water. The regime will vary, depending on requirements.

However CIP can be ineffective – and even cause damage and contribute to filter blockages – if the regime is not tailored correctly. Again, this can increase spend on consumables and lead to more downtime.

Chemicals used in CIP regimes can potentially put filter integrity at risk and the high temperature required to facilitate the breakdown of blockage materials poses a risk to the filter construct too.

Parker’s Technical Support Group offers guidance on the compatibility of filters with CIP regimes, and can recommend solutions that optimise CIP regimes and ensure that filter integrity is maintained.

Integrity testing will also help operators to identify if a CIP regime is damaging filters… and filters should be integrity tested after CIP to ensure their integrity before processing takes place.

Our Bevcheck portable semi-automated integrity testing units and Bevcheck Plus fully automated integrity testing units have been developed to support breweries in this.

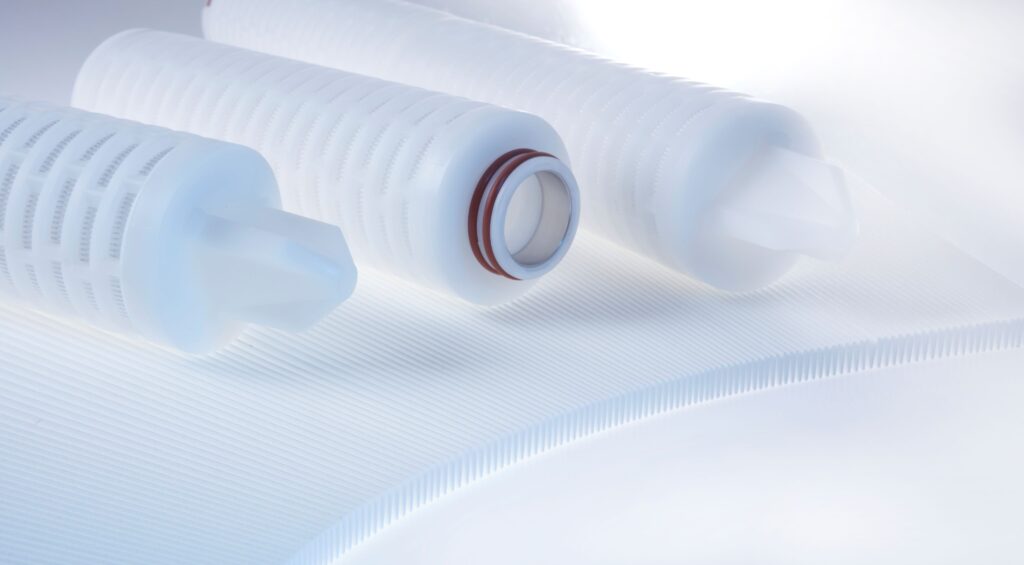

Above: ParkerBevpor BR filters

Technology and methodologies are continuing to evolve, as demand for more energy efficient solutions surges.

Parker, for instance, is exploring the potential for a greater use of enzymes in CIP regimes, which can work at lower temperatures than caustic washes, thus helping breweries to reduce energy consumption.

Switching from flash pasteurisation to cold stabilisation is just one part of the journey to greater efficiency. Accessing the specialist expertise needed to optimise filtration systems and CIP regimes, and embracing innovation, are also key.

Combined, these elements can help breweries save time and money, reduce their carbon footprints, and create a more sustainable future.