When did brewing beer become a chore?” asks Darin Haener, founder of Fermentable. “I have fond memories of the days that I would roll out my custom 10-gallon brew deck into the backyard and spend the morning relishing in the aroma of malted barley and boiling hops. Then I’d spend the rest of that afternoon enjoying the spoils of last month’s brews and conversing with great friends.”

Fermentable was created by Haener, a professional brewer who experienced first-hand how frustrating it was to manage the brewery’s day-to-day operations. “Your business is brewing beer, not managing spreadsheets, compiling TTB reports, and fumbling through brew logs. We know the in’s and out’s of the industry and what it takes to get the paperwork out of the way, so you can get brewing,” he says.

Those early experiences are why he originally chose brewing as a profession. For the first years of his professional career, Haener was learning and continuing to grow as a brewer, and he developed a passion for creating works of art in a pint glass. It wasn’t until he started managing his own breweries that he began to understand the pain of actually running a brewery as a business.

He explains: “Maintaining impeccable records, keeping hops that were frequently unavailable from suppliers in stock so I didn’t run out of the precious West Coast IPA, and struggling to remember where I put my pen so I could record my mash out time were just a few of the headaches that began to consume the majority of my time as a ‘brewer’.

“I began to lose sight of what it was that drove me to choose a life of schlepping spent-grain and dragging hoses. Managing the business side of my brewery had begun to suck the passion out of my career. I wanted to remember why I started brewing in the first place, and this set-in-motion my first attempt to hone my business operations.

“I started with an assortment of spreadsheets for tracking inventory and forecasting ordering, which grew into another mess with a whole new set of problems. Deciphering bad handwriting and wort smudged brew logs was doing nothing but detracting me from formulating my next masterpiece. Management software quickly became the clear choice for solving these problems.”

For Haener, finding a solution to help automatically track inventory, generate reports, and rid the brewery of paper documents was going to be a big win for his breweries. At that time, he explains, brewery management software solutions did not exist, so he continued with spreadsheets, longing for the day that I could use a piece of streamlined software to make managing my brewery operations easier.

“Fortunately, today, there are a wide variety of platforms out there that can help with these issues. From free schedulers to full-fledged enterprise level Enterprise Resource Planning (ERP) systems, if you’re struggling with your management and need help, there is a software solution that will meet your brewery’s needs and budget,” he says.

“All that said, management software isn’t for everyone. If you have a small brewery that is making a few hundred barrels of beer a year, your operations are dialled in, and you aren’t looking to grow much beyond your current production, it probably doesn’t make sense to spend the time and money to invest in a system that is built to help you grow as a brewery.”

Haener concludes: “However, if growth is your goal, it’s a good idea to start looking at ways to streamline your business, and management software is a great place to start.”

Inventory and production management

Brew Love Software is a brewery management software helping breweries ranging in size from startup to 10,000 BBLS of production to manage their ingredient inventory and production in one tool.

According to Russell Miller, founder of the business, customers are looking to manage their production with as little mental energy as possible. Brewers ask for a tool they can use without spending hours on the computer jumping from one spreadsheet to the next, updating and trying to remember to save a new version each time.

They want something that takes away some of the demand on their attention so they can focus on brewing and growing their business. They also want reports that tell them what their business is doing, as well as reports they can use to provide their numbers to the government as required.

Brew Love Software’s offering is based around one software package. It focuses on breweries from start-up to around 15k BBLS/Year (~18k HL/Yr), where often one brewer runs most of the show. The tools are the same whether your goal is to grow your brewery or just optimise production for the equipment you’ve got.

He explains: “What you really need is to know your numbers. Brew Love helps you prepare orders of raw materials in time to meet your production schedule, determine the real cost of goods for finished beer, keep track of your kegs and know who still hasn’t returned them, and maintain production records in case of government audits.

“It also helps manage customers’ beer orders, track barrel ageing, remind you to make payments for materials before they are overdue and to get paid for your beer, automatically update your raw material inventory when a batch is started, log losses, track quality control, and manage beer inventory.”

For Miller, effective investment in the software side of your business helps answer a key question: “How do you know what’s making money and what’s costing you money if you’re not tracking it?”

He adds: “If you’re on the fence about software, let me ask you something. If you really think about it, how much of your mental energy and attention do you spend trying to make your brewery run efficiently and cost effectively? Simply put, software can reduce the time and energy you spend keeping your business successful. Or, perhaps software can help you get to efficiently managing your costs for the first time.

“Maybe you’ve already got a process in place. How many moving parts does it have and how many points of possible failure? Assess where you are with your business. Are you exactly where you want to be? Are your costs controlled? I like the saying, if you keep doing what you’re already doing, you’ll keep getting the results you’re already getting. Are you happy with those results?

“Software reminds you of actions so you don’t have to remember everything yourself, it automates time consuming tasks that you are currently doing manually, it keeps digital records for you so that data is easily accessible and usable, not stuck on paper somewhere in a drawer full of files. Software works in ways you only wish spreadsheets could.

“You probably got in business to make great beer and to make good money in the process. How do you know what’s making money and what’s costing you money if you’re not tracking it? Software will allow you to focus on making good beer and to expend less effort on the business of making it.”

Small Pack Focus

For Nigel Hoppitt, director at brewery management systems firm Spasoft, he’s observed a particular shift in the arena of beer packaging.

“Beer packaging is changing especially in small-pack products, the range in supermarkets has increased giving more breweries access to new outlets. Breweries are looking for more automation and improved data recording and retention, which we have always excelled at and offered solutions focussed on accuracy,” he explains.

“Currently we are preparing a release that will improve the management of the wide range of small-pack containers and pack sizes into account, speeding up order entry and offering pre-allocation of stock by batch/datecode,” sats Hoppitt.

“Our system already forces accuracy in shipping and delivery, moving stock allocation one step earlier assists with stock management for larger customers and ensures customers get what they need and makes the stock allocation faster. Planning production and stock gets easier with the new Production Schedule module. A graphical interface shows tank utilisation, beer stock availability and highlights potential raw stock shortages. This module will also lead into our new GUI format for rollout throughout 2018.”

For Hoppitt, it’s not surprising to see an increasing number of breweries place a stronger emphasis on the online side of their business.

As breweries grow and their market changes, they need more time for their customers and brewing their beers. Adding a system to their business is more efficient, tracking contact with the customers, having their contact and order history to hand, accurately entering orders, knowing what has gone where, and preventing production issues by having the right amount of stock in place. Producing a monthly duty report at the click of a button saves hours compared to an accounts package or interlinked excel spreadsheets, he says.

“Reliable cloud-based solutions are the answer. They remove the data integrity issue from the brewery, offer secure access from any location and give flexibility to support the many ways in which breweries work. It is cost effective and painless to migrate from spreadsheets and paper to a complete cloud-based solution that gives a seamless and economic solution end to end.

“Our solution is available for less than the cost of a High Street coffee a day. Your data integrity is our responsibility. We ensure the security of your data including backups and disaster recovery, plus the uptime of our servers, maintaining your access to your data.”

The Pain Points of Brewing

by Ben Morgan-Smith, co-founder of BrewBroker

There are a number of pain-points that exist in the brewing industry. Ben Morgan-Smith, co-founder of BrewBroker addresses some of them.

Setting up a brewery is extremely expensive and without a solid pipeline of orders carries a significant amount of risk for brewers at the start of their journey.

The risk and cost of growing into a facility: One way to balance the investment is to embark on building a facility a business can grow in to. It still carries risk (more risk in fact) but allows that initial investment to be spread over a longer period higher volume of orders/more revenue.

Container conundrums: 330ml cans have been the vogue container for certainly the craft beer sector of the market. However, only certain producers have had access to canning facilities. Quick thinkers have set up business to try and deal with the shortfall have moved the industry on (We Can/Them That Can for example). However, it took time for the UK market to catch up with demand. Buying kegs is also a large expense. One-way kegs have offered an alternative solution through suppliers such as Kegstar.

Craft market behaviour

Particularly in the on trade, the dynamic of ‘listings’ has changed. The Craft Beer movement by its nature encourages the end user to have a promiscuous purchasing habit.

This means a single ‘listing’ in an outlet is unlikely to deliver the volume it once would have, as consumer demand is meaning outlets rotate their stock and range extremely regularly. An approach of brewers to defend against this is to have a strategy that creates a larger footprint, either by an increased range of products, or geographical reach, including international trade.

However, distribution at scale can be challenging for a new, rapidly growing brand, especially in the very fragmented UK market place. Concepts like Eebria Trade and Sparetap is a huge step towards a world where it will be easier for pubs and retailers to order products directly, so the landscape is likely to continue to evolve.

Breaking into new markets: Getting beer onto the Continent or over to the States, New Zealand and Australia carries many challenges. The cost of shipping – most commonly on a container ship – is costly and adds to the challenge of keeping the beer fresh. It can take weeks to move product from one market to another, reducing the shelf life but also risking a reduction in quality due to the rigours of long haul transit.

The food miles: The environmental cost of moving beer long distances, no matter what the container/method of transport is significant and could be lessened if the product could be produced closer to, or in market of end use. This is especially relevant with the product that would ideally be refrigerated throughout the entire process.

Potential solution

Working with partners to reduce the risk could offer a solution, via an asset sharing economy. In short using the capacity already in the marketplace rather than building a new facility. With brewing, this would lessen the strain on those with spare capacity in their brewery (through either having room to grow or a downturn in demand), as well as new entrants into the market or those experiencing rapid growth that do not have facilities available.

For packaging, it would allow for the same progress, existing plants/facilities being fully utilised for the benefit of both the buying and selling party.This happens to an extent already, and some brewers build it into their story as an added reason to believe. However, the process of finding partners, developing trust and progressing to a transaction is a long and drawn out process that is creating waste in itself.

As a buyer, the online marketplace can instantly match you with an initial list of supplier who are able to fulfil your order (as oppose to manually ringing countless options), and then progress on to creating a tender, receive and compare a number of quotes from a shortlist of suitors, before going onto managing the transaction through a sophisticated payment system.

As a supplier of brewing and packaging services, the system means you are only presented with tenders that suit your capacity/capabilities, so no time is wasted progressing conversations with buyers that won’t progress in a deal.

The opportunity

This digital evolution in the brewing industry can mean new entrants, or those experiencing rapid growth, can produce a product easily without huge investment in new facilities, and those with spare capacity can maximise the income possible from their assets. It can open up producers to a larger range of options of containers and packaging.

This means that producers can lower their environmental footprint, cost-effectively and with the best possible version of their product in market.

Barrel Management

A US brewer recently commented that if you’re a brewery in 2018 and you don’t have a selection of barrels out the back “people look at you funny”, and that’s a trend we’re increasing seeing in the UK and Ireland. Barrel-ageing programmes enable brewers to diversify their product offering, and many are seeing this side of their business grow at a rapid pace, according to Sam Babikian, co-owner of Barrel-IT from ZymurTech.

Barrel-IT is a web-based software used as a Service (SaaS) application. It was built from the ground up to increase visibility of what is happening in your oak cellar. This ranges from the logistical aspects of receiving barrels, filling them and blending them to locating them, emptying them, and reusing or selling them off, which can all be done with a few clicks.

He explains: “Our Quality Control module can be used to track different post fermentation/distillation data attributes and assures that only barrels of a certain quality go into the final product. The Scoring module can be used for group sensory analysis to help determine specific attributes or characteristic of each barrel, with the data from these modules then being used to help create a blend plan or a product release. This system not only tells you where your barrels are physically located but what’s been in them and what additions, if any, where added.

“It tracks the complete history of each barrel or as we say “who did what to it when and where”. Lastly, Barrel-It is a decentralized system, meaning that permission or access can be granted to each user at a module level. For example, you can provide access to your cellar man, QA/QC lab, or your sensory testers just to the modules they need.”

According to Sam Babikian, US-based Barrel-IT’s clients range in size, with some having as few as 60 barrels to some that have over 10,000. The general feedback Babikian and his team receive is that when oak cellars get close to around 60 or 70 barrels, things get very difficult to manage using spreadsheets.

“Some of our clients with smaller programs jumped on board early knowing they are going to expand and they wanted to have the complete history of their entire program in Barrel-IT. So, even for breweries that have smaller barrel programs our price point is such that even they get good value using our software,” he says. “When you think about it, the retail cost potential of even one barrel of product is at least $5,000 or more. We have had clients say that if the software prevents the loss of one barrel or better yet helps prevent one bad barrel from ruining an entire blend, it’s already paid for itself for many years.”

Babikian echoes what we’ve already heard, and goes on to add: “The bottom line is investing in the right software will save you money. The things to remember are that when implementing software is there will always be a bit of culture shock and of course a learning curve. However, these issues can be minimized by being selective of the software you choose.

“Put together a list of features that is important to you and try to find one the hits most of what is on that list. For the ones that are not on the list think about how you might be able to change or adapt your process to make it work.

“When you talk to software companies find out their response times for how quickly they can patch or update problems. No software is perfect, they all have bugs in there somewhere. Lastly, see how perceptive they are to adding functionality and future changes or new ideas. If your idea is one that would help other clients as well and make the overall application better that should be enough incentive for them to add it to their roadmap for a future release,” says Babikian.

Brewery management

“I spoke with a brewer yesterday who is typical. They have 35 spreadsheets that all need to be kept up to date and, once each month, he needs to generate reports for government tax authorities – who take a dim view of inaccurate information. He said it used to take him a half day to do it, but as he has grown, it now takes him three days to do these mandatory reports. He said he wanted to buy some of his time back,” explains Dr Will Bralick, founder of Iconic BMS

Bralick says: “I described to him how our system operates: you follow standard operating procedures – those defined by how the system works – to handle purchasing raw materials, receiving them, managing them in inventory (lot/serial control, expiration dates), using them in production to produce beer which is then sold using the POS or B2B sales process and then ship the product.

“All of those activities are the natural activities of the brewery – so nothing unusual there. At the end of the month, if the processes have been followed reliably, then the click of a button produces the necessary reports. When I described how our system operates along these lines he sounded like he had found nirvana.

“One significant advantage of a system like this is that it creates an opportunity for the business of the brewery to be continually refined and improved upon. Improving efficiency across the organization is achieved by improving the efficiency of the system. Before a process can be improved it must be consistent. An automated system imposes this necessary consistency on the users.

“Often the impact of a system like this is immeasurable. Impact is change. Although the users can experience the change, they cannot say how much (or whether) it has improved things because before the system is implemented, most of the business operations are not measured. Once the system is in place, those measurements can be taken.”

The digital brewer

When did brewing beer become a chore?” asks Darin Haener, founder of Fermentable. “I have fond memories of the days that I would roll out my custom 10-gallon brew deck into the backyard and spend the morning relishing in the aroma of malted barley and boiling hops. Then I’d spend the rest of that afternoon enjoying the spoils of last month’s brews and conversing with great friends.”

Fermentable was created by Haener, a professional brewer who experienced first-hand how frustrating it was to manage the brewery’s day-to-day operations. “Your business is brewing beer, not managing spreadsheets, compiling TTB reports, and fumbling through brew logs. We know the in’s and out’s of the industry and what it takes to get the paperwork out of the way, so you can get brewing,” he says.

Those early experiences are why he originally chose brewing as a profession. For the first years of his professional career, Haener was learning and continuing to grow as a brewer, and he developed a passion for creating works of art in a pint glass. It wasn’t until he started managing his own breweries that he began to understand the pain of actually running a brewery as a business.

He explains: “Maintaining impeccable records, keeping hops that were frequently unavailable from suppliers in stock so I didn’t run out of the precious West Coast IPA, and struggling to remember where I put my pen so I could record my mash out time were just a few of the headaches that began to consume the majority of my time as a ‘brewer’.

“I began to lose sight of what it was that drove me to choose a life of schlepping spent-grain and dragging hoses. Managing the business side of my brewery had begun to suck the passion out of my career. I wanted to remember why I started brewing in the first place, and this set-in-motion my first attempt to hone my business operations.

“I started with an assortment of spreadsheets for tracking inventory and forecasting ordering, which grew into another mess with a whole new set of problems. Deciphering bad handwriting and wort smudged brew logs was doing nothing but detracting me from formulating my next masterpiece. Management software quickly became the clear choice for solving these problems.”

For Haener, finding a solution to help automatically track inventory, generate reports, and rid the brewery of paper documents was going to be a big win for his breweries. At that time, he explains, brewery management software solutions did not exist, so he continued with spreadsheets, longing for the day that I could use a piece of streamlined software to make managing my brewery operations easier.

“Fortunately, today, there are a wide variety of platforms out there that can help with these issues. From free schedulers to full-fledged enterprise level Enterprise Resource Planning (ERP) systems, if you’re struggling with your management and need help, there is a software solution that will meet your brewery’s needs and budget,” he says.

“All that said, management software isn’t for everyone. If you have a small brewery that is making a few hundred barrels of beer a year, your operations are dialled in, and you aren’t looking to grow much beyond your current production, it probably doesn’t make sense to spend the time and money to invest in a system that is built to help you grow as a brewery.”

Haener concludes: “However, if growth is your goal, it’s a good idea to start looking at ways to streamline your business, and management software is a great place to start.”

Inventory and production management

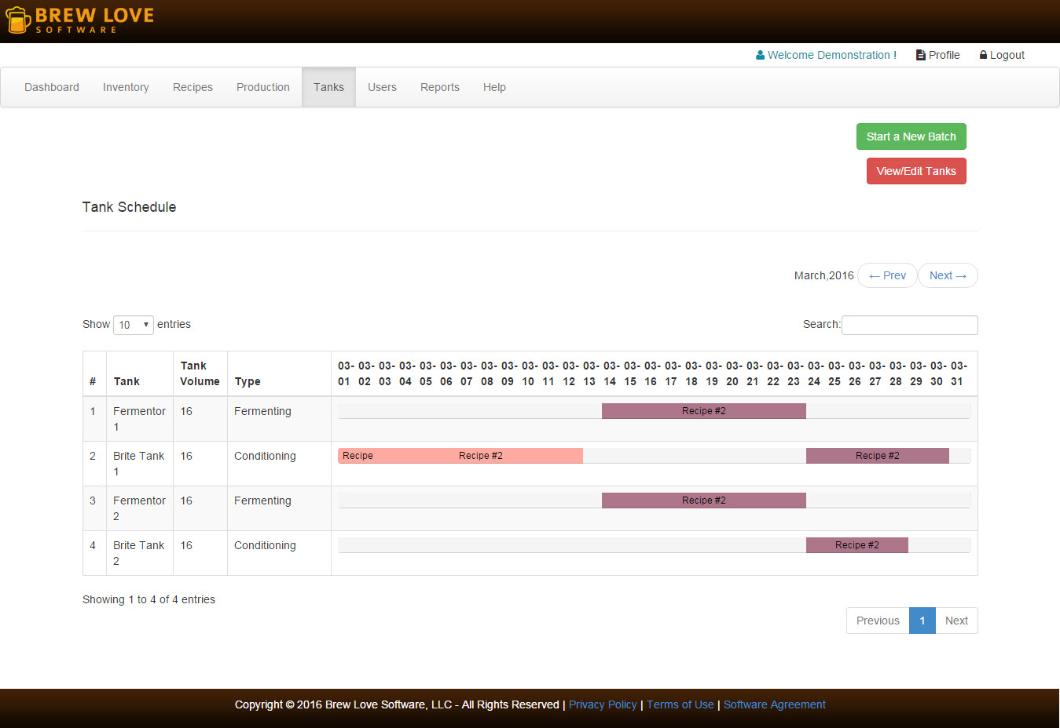

Brew Love Software is a brewery management software helping breweries ranging in size from startup to 10,000 BBLS of production to manage their ingredient inventory and production in one tool.

According to Russell Miller, founder of the business, customers are looking to manage their production with as little mental energy as possible. Brewers ask for a tool they can use without spending hours on the computer jumping from one spreadsheet to the next, updating and trying to remember to save a new version each time.

They want something that takes away some of the demand on their attention so they can focus on brewing and growing their business. They also want reports that tell them what their business is doing, as well as reports they can use to provide their numbers to the government as required.

Brew Love Software’s offering is based around one software package. It focuses on breweries from start-up to around 15k BBLS/Year (~18k HL/Yr), where often one brewer runs most of the show. The tools are the same whether your goal is to grow your brewery or just optimise production for the equipment you’ve got.

He explains: “What you really need is to know your numbers. Brew Love helps you prepare orders of raw materials in time to meet your production schedule, determine the real cost of goods for finished beer, keep track of your kegs and know who still hasn’t returned them, and maintain production records in case of government audits.

“It also helps manage customers’ beer orders, track barrel ageing, remind you to make payments for materials before they are overdue and to get paid for your beer, automatically update your raw material inventory when a batch is started, log losses, track quality control, and manage beer inventory.”

For Miller, effective investment in the software side of your business helps answer a key question: “How do you know what’s making money and what’s costing you money if you’re not tracking it?”

He adds: “If you’re on the fence about software, let me ask you something. If you really think about it, how much of your mental energy and attention do you spend trying to make your brewery run efficiently and cost effectively? Simply put, software can reduce the time and energy you spend keeping your business successful. Or, perhaps software can help you get to efficiently managing your costs for the first time.

“Maybe you’ve already got a process in place. How many moving parts does it have and how many points of possible failure? Assess where you are with your business. Are you exactly where you want to be? Are your costs controlled? I like the saying, if you keep doing what you’re already doing, you’ll keep getting the results you’re already getting. Are you happy with those results?

“Software reminds you of actions so you don’t have to remember everything yourself, it automates time consuming tasks that you are currently doing manually, it keeps digital records for you so that data is easily accessible and usable, not stuck on paper somewhere in a drawer full of files. Software works in ways you only wish spreadsheets could.

“You probably got in business to make great beer and to make good money in the process. How do you know what’s making money and what’s costing you money if you’re not tracking it? Software will allow you to focus on making good beer and to expend less effort on the business of making it.”

Small Pack Focus

For Nigel Hoppitt, director at brewery management systems firm Spasoft, he’s observed a particular shift in the arena of beer packaging.

“Beer packaging is changing especially in small-pack products, the range in supermarkets has increased giving more breweries access to new outlets. Breweries are looking for more automation and improved data recording and retention, which we have always excelled at and offered solutions focussed on accuracy,” he explains.

“Currently we are preparing a release that will improve the management of the wide range of small-pack containers and pack sizes into account, speeding up order entry and offering pre-allocation of stock by batch/datecode,” sats Hoppitt.

“Our system already forces accuracy in shipping and delivery, moving stock allocation one step earlier assists with stock management for larger customers and ensures customers get what they need and makes the stock allocation faster. Planning production and stock gets easier with the new Production Schedule module. A graphical interface shows tank utilisation, beer stock availability and highlights potential raw stock shortages. This module will also lead into our new GUI format for rollout throughout 2018.”

For Hoppitt, it’s not surprising to see an increasing number of breweries place a stronger emphasis on the online side of their business.

As breweries grow and their market changes, they need more time for their customers and brewing their beers. Adding a system to their business is more efficient, tracking contact with the customers, having their contact and order history to hand, accurately entering orders, knowing what has gone where, and preventing production issues by having the right amount of stock in place. Producing a monthly duty report at the click of a button saves hours compared to an accounts package or interlinked excel spreadsheets, he says.

“Reliable cloud-based solutions are the answer. They remove the data integrity issue from the brewery, offer secure access from any location and give flexibility to support the many ways in which breweries work. It is cost effective and painless to migrate from spreadsheets and paper to a complete cloud-based solution that gives a seamless and economic solution end to end.

“Our solution is available for less than the cost of a High Street coffee a day. Your data integrity is our responsibility. We ensure the security of your data including backups and disaster recovery, plus the uptime of our servers, maintaining your access to your data.”

The Pain Points of Brewing

by Ben Morgan-Smith, co-founder of BrewBroker

There are a number of pain-points that exist in the brewing industry. Ben Morgan-Smith, co-founder of BrewBroker addresses some of them.

Setting up a brewery is extremely expensive and without a solid pipeline of orders carries a significant amount of risk for brewers at the start of their journey.

The risk and cost of growing into a facility: One way to balance the investment is to embark on building a facility a business can grow in to. It still carries risk (more risk in fact) but allows that initial investment to be spread over a longer period higher volume of orders/more revenue.

Container conundrums: 330ml cans have been the vogue container for certainly the craft beer sector of the market. However, only certain producers have had access to canning facilities. Quick thinkers have set up business to try and deal with the shortfall have moved the industry on (We Can/Them That Can for example). However, it took time for the UK market to catch up with demand. Buying kegs is also a large expense. One-way kegs have offered an alternative solution through suppliers such as Kegstar.

Craft market behaviour

Particularly in the on trade, the dynamic of ‘listings’ has changed. The Craft Beer movement by its nature encourages the end user to have a promiscuous purchasing habit.

This means a single ‘listing’ in an outlet is unlikely to deliver the volume it once would have, as consumer demand is meaning outlets rotate their stock and range extremely regularly. An approach of brewers to defend against this is to have a strategy that creates a larger footprint, either by an increased range of products, or geographical reach, including international trade.

However, distribution at scale can be challenging for a new, rapidly growing brand, especially in the very fragmented UK market place. Concepts like Eebria Trade and Sparetap is a huge step towards a world where it will be easier for pubs and retailers to order products directly, so the landscape is likely to continue to evolve.

Breaking into new markets: Getting beer onto the Continent or over to the States, New Zealand and Australia carries many challenges. The cost of shipping – most commonly on a container ship – is costly and adds to the challenge of keeping the beer fresh. It can take weeks to move product from one market to another, reducing the shelf life but also risking a reduction in quality due to the rigours of long haul transit.

The food miles: The environmental cost of moving beer long distances, no matter what the container/method of transport is significant and could be lessened if the product could be produced closer to, or in market of end use. This is especially relevant with the product that would ideally be refrigerated throughout the entire process.

Potential solution

Working with partners to reduce the risk could offer a solution, via an asset sharing economy. In short using the capacity already in the marketplace rather than building a new facility. With brewing, this would lessen the strain on those with spare capacity in their brewery (through either having room to grow or a downturn in demand), as well as new entrants into the market or those experiencing rapid growth that do not have facilities available.

For packaging, it would allow for the same progress, existing plants/facilities being fully utilised for the benefit of both the buying and selling party.This happens to an extent already, and some brewers build it into their story as an added reason to believe. However, the process of finding partners, developing trust and progressing to a transaction is a long and drawn out process that is creating waste in itself.

As a buyer, the online marketplace can instantly match you with an initial list of supplier who are able to fulfil your order (as oppose to manually ringing countless options), and then progress on to creating a tender, receive and compare a number of quotes from a shortlist of suitors, before going onto managing the transaction through a sophisticated payment system.

As a supplier of brewing and packaging services, the system means you are only presented with tenders that suit your capacity/capabilities, so no time is wasted progressing conversations with buyers that won’t progress in a deal.

The opportunity

This digital evolution in the brewing industry can mean new entrants, or those experiencing rapid growth, can produce a product easily without huge investment in new facilities, and those with spare capacity can maximise the income possible from their assets. It can open up producers to a larger range of options of containers and packaging.

This means that producers can lower their environmental footprint, cost-effectively and with the best possible version of their product in market.

Barrel Management

A US brewer recently commented that if you’re a brewery in 2018 and you don’t have a selection of barrels out the back “people look at you funny”, and that’s a trend we’re increasing seeing in the UK and Ireland. Barrel-ageing programmes enable brewers to diversify their product offering, and many are seeing this side of their business grow at a rapid pace, according to Sam Babikian, co-owner of Barrel-IT from ZymurTech.

Barrel-IT is a web-based software used as a Service (SaaS) application. It was built from the ground up to increase visibility of what is happening in your oak cellar. This ranges from the logistical aspects of receiving barrels, filling them and blending them to locating them, emptying them, and reusing or selling them off, which can all be done with a few clicks.

He explains: “Our Quality Control module can be used to track different post fermentation/distillation data attributes and assures that only barrels of a certain quality go into the final product. The Scoring module can be used for group sensory analysis to help determine specific attributes or characteristic of each barrel, with the data from these modules then being used to help create a blend plan or a product release. This system not only tells you where your barrels are physically located but what’s been in them and what additions, if any, where added.

“It tracks the complete history of each barrel or as we say “who did what to it when and where”. Lastly, Barrel-It is a decentralized system, meaning that permission or access can be granted to each user at a module level. For example, you can provide access to your cellar man, QA/QC lab, or your sensory testers just to the modules they need.”

According to Sam Babikian, US-based Barrel-IT’s clients range in size, with some having as few as 60 barrels to some that have over 10,000. The general feedback Babikian and his team receive is that when oak cellars get close to around 60 or 70 barrels, things get very difficult to manage using spreadsheets.

“Some of our clients with smaller programs jumped on board early knowing they are going to expand and they wanted to have the complete history of their entire program in Barrel-IT. So, even for breweries that have smaller barrel programs our price point is such that even they get good value using our software,” he says. “When you think about it, the retail cost potential of even one barrel of product is at least $5,000 or more. We have had clients say that if the software prevents the loss of one barrel or better yet helps prevent one bad barrel from ruining an entire blend, it’s already paid for itself for many years.”

Babikian echoes what we’ve already heard, and goes on to add: “The bottom line is investing in the right software will save you money. The things to remember are that when implementing software is there will always be a bit of culture shock and of course a learning curve. However, these issues can be minimized by being selective of the software you choose.

“Put together a list of features that is important to you and try to find one the hits most of what is on that list. For the ones that are not on the list think about how you might be able to change or adapt your process to make it work.

“When you talk to software companies find out their response times for how quickly they can patch or update problems. No software is perfect, they all have bugs in there somewhere. Lastly, see how perceptive they are to adding functionality and future changes or new ideas. If your idea is one that would help other clients as well and make the overall application better that should be enough incentive for them to add it to their roadmap for a future release,” says Babikian.

Brewery management

“I spoke with a brewer yesterday who is typical. They have 35 spreadsheets that all need to be kept up to date and, once each month, he needs to generate reports for government tax authorities – who take a dim view of inaccurate information. He said it used to take him a half day to do it, but as he has grown, it now takes him three days to do these mandatory reports. He said he wanted to buy some of his time back,” explains Dr Will Bralick, founder of Iconic BMS

Bralick says: “I described to him how our system operates: you follow standard operating procedures – those defined by how the system works – to handle purchasing raw materials, receiving them, managing them in inventory (lot/serial control, expiration dates), using them in production to produce beer which is then sold using the POS or B2B sales process and then ship the product.

“All of those activities are the natural activities of the brewery – so nothing unusual there. At the end of the month, if the processes have been followed reliably, then the click of a button produces the necessary reports. When I described how our system operates along these lines he sounded like he had found nirvana.

“One significant advantage of a system like this is that it creates an opportunity for the business of the brewery to be continually refined and improved upon. Improving efficiency across the organization is achieved by improving the efficiency of the system. Before a process can be improved it must be consistent. An automated system imposes this necessary consistency on the users.

“Often the impact of a system like this is immeasurable. Impact is change. Although the users can experience the change, they cannot say how much (or whether) it has improved things because before the system is implemented, most of the business operations are not measured. Once the system is in place, those measurements can be taken.”

ARTICLES

BarthHaas presents new water-based hop products

Sustainability | It’s time for change

Burning Sky and St Austell collab

SIBA launches manifesto ahead of next General Election

PODCASTS