Weisse beer has undergone somewhat of a resurgence. Beers produced by traditional brewers of the style are popular not just in the traditional southern German heartlands but also worldwide. And there are practical steps a brewer can take to influence the yeast derived Esters and Phenols present in Wheat Beer as well as in other beers, explains Andrew Paterson, technical sales and support for the UK at Lallemand Brewing.

Wheat beer is a broad style of top fermenting beer traditional to the regions of Southern Germany, including Bavaria and Baden-Württemberg, as well as parts of Austria. The terms Weissbier (white beer) or Weizenbier (wheat beer) are used synonymously to denote the style.

The first beers brewed and labelled as Weissbier were brewed in the 1500s by the aristocratic Degenberger family, who were awarded the exclusive right to brew the style in the Bavarian forest region, as well as in Bohemia, by Duke Wilhelm IV. The brewery itself was established in the town of Schwarzach and the beers produced were seen to be the preserve of the gentry [1].

On the subsequent death of the head of the Degenberger family, Baron Hans Sigmund Degenberger, the rights to brew Weissbier passed to Duke Maximilian I of Bavaria. Seeing the economic potential the Duke opened several more Weiss breweries including one in Munich, now the site of the iconic Hofbräuhaus, and one in Kelheim, which would later become the famous Schneider Weisse brewery [1].

The popularity of the style boomed through the 1700s but the invention of refrigeration and competition from the new bottom fermenting styles (lager) caused sales to decrease to the point of unprofitability. Were it not for the insight of Georg Schneider who opened the original Schneider brewery in Munich in 1872 the Weisse style might have died out completely [1].

These days Weisse beer has undergone somewhat of a resurgence with beers produced by traditional brewers of the style popular not just in the traditional southern German heartlands but worldwide. The style, while not as frequently reproduced as the now ubiquitous IPA, has also been much imitated by craft brewers across the globe

Key characteristics

When we think of Weissbier we think of an almost pearlescent, opaque beer with a large rocky head of foam, usually served in an oversized glass. Aromas of banana and clove hit the nose, (if the foam doesn’t first) and fruity flavours along with a slight tartness and zing due to very high levels of carbonation fill the mouth. Indeed the theatre and performance associated with drinking Weissbier may have much to do with its modern day success; you feel like you’ve won a prize every time you go to the bar.

This is the classic punter’s view of Weiss beer, in fact the style is quite broad and can be divided into Hefeweizen, (containing yeast) and Kristallweizen (filtered and bright). Hefeweizen is by far the more popular of the two. These two types can be further broken down into Weizenbier (Standard Wheat Beer), Dunkelweizen (Dark Wheat Beer) and Weizenbock (Wheat Beer brewed in the Bock style). Alkoholfrei (free from alcohol) beers are also popular in this category.

Origins of key distinguishing characteristics

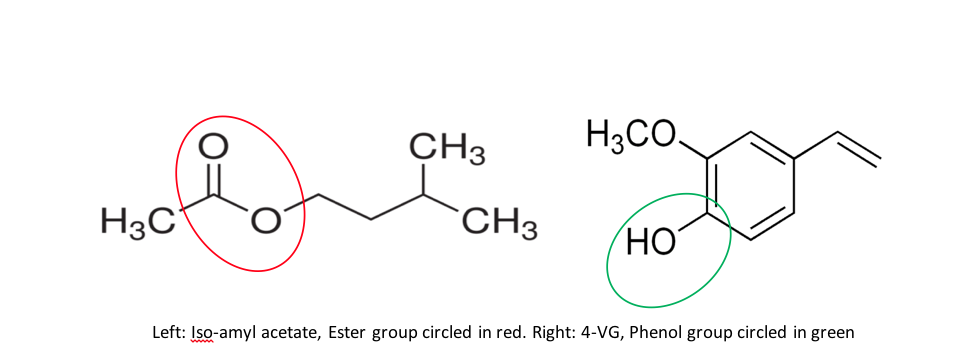

Two of the key distinguishing flavour characteristics of Wheat Beer, Clove and Banana, have their origins in both the raw ingredients used for the grist and in the yeast strain chosen for the fermentation. Chemically the flavours can be broken down into two distinct groups. Banana or Iso-amyl acetate is an Ester and is produced as a by-product of yeast metabolism, while Clove or 4-vinyl-guiacol (4-VG) is a phenol and is produced by the action of yeast on chemicals originating from Malted Barley and Wheat.

Phenol formation

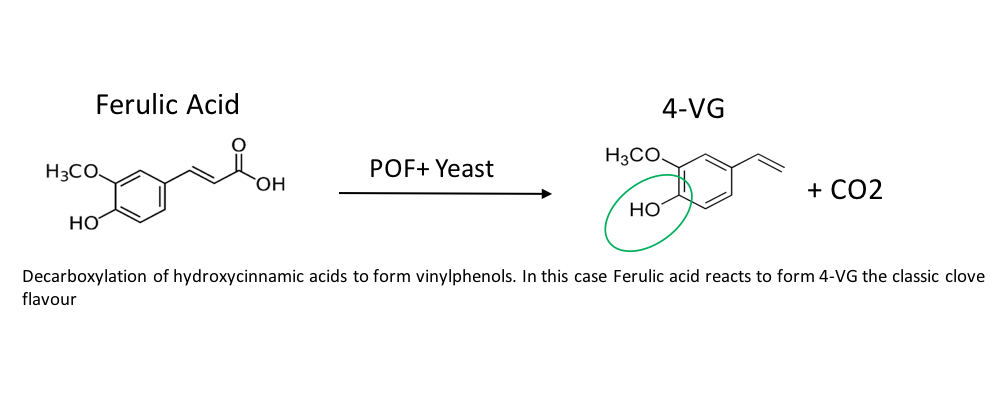

The Phenol character present in Wheat Beer is derived from enzyme catalysed reactions with a series of chemicals called hydroxycinnamic acids. These chemicals are abundant in plant cell walls and have both a structural role as well as contributing to the plants defence mechanism against pathogenic micro-organisms [2].

The two most common Phenols present are the previously mentioned 4-VG (Clove), derived from Ferulic acid, as well as the related 4-VP, derived from P-Coumaric acid. 4-VP whilst usually present at low levels has an unpleasant character, usually described as bandaid or medicinal; its presence at levels above its flavour threshold is usually considered as a fault.

Phenols are created from hydroxycinnamic acids by active enzymatic decarboxylation by yeast strains possessing the Phenolic Off Flavour (POF+) phenotype. The original wild type ancestor of modern brewing yeast strains probably possessed this trait. However, genetic selection pressures of continuous re-pitching has led to most brewing strains losing this ability.

While no longer present in most brewing yeasts, the characteristic prevailed in many strains used for the production of Belgian Beers, Saisons and German Wheat Beers contributing to part of their distinct character. Examples of such strains are Lalbrew Abbaye, Lalbrew Munich Classic, Lalbrew Munich Wheat and Lalbrew Belle Saison.

Controlling Phenol formation

As outlined above 4-VG is produced by the enzymatic transformation of Ferulic Acid present in Barley and Wheat. Understanding the role of yeast in the formation of the chemical is one thing but what are the practical steps a brewer can take to control the level and formation of 4-VG?

Mashing – Studies have found that Ferulic acid is most often present in a bound (esterified) form in the cell wall and must be liberated by enzymes named Feruloyl Esterases in order to be released into solution. These enzymes are most active at a temperature of 45 degrees and a pH of 5.8 [3]. As such, and if mashing equipment allows, it is ideal to mash in at a starting temperature of 45 degrees prior to proceeding to the sacchrification step.

Choice of grist – While overall, Wheat Malt has a marginally higher level of Ferulic Acid than Barley, studies have shown that more Ferulic Acid is released from a pure Barley Malt mash than one consisting entirely of Wheat Malt [3]. To further complicate the picture it would appear that bound Ferulic acid is also released from Wheat Malt worts during fermentation, indicating some level of Feruloyl Esterase activity in POF+ strains [3].

This does not take place in worts produced from Malted Barley showing specificity for the bound form of Ferulic Acid found in Wheat. Studies on the subject suggest the ratio of Barley Malt to Wheat Malt required to produce the most 4-VG is in the region of 70:30 [3].

Pressure – It has been shown that using open top tanks at atmospheric pressure increases the levels of 4-VG in Wheat Beers. Fortuitously this has also been shown to decrease the levels of Styrene, another related, but undesirable, hydroxycinnamic acid derivative in finished beer [4].

Yeast strain – As already mentioned, a yeast strain should be chosen which displays the POF+ phenotype if this character is required. There are many to choose from and care must be taken when making a choice. Your yeast supplier should be able to help in this regard. Some wheat beer strains are also classified as var. diastaticus meaning they possess the STA gene and are able to effectively metabolise dextrins. For a more detailed explanation of diastaticus yeasts and the STA gene please see the previous issue by Robert Percival [5].

Ester formation

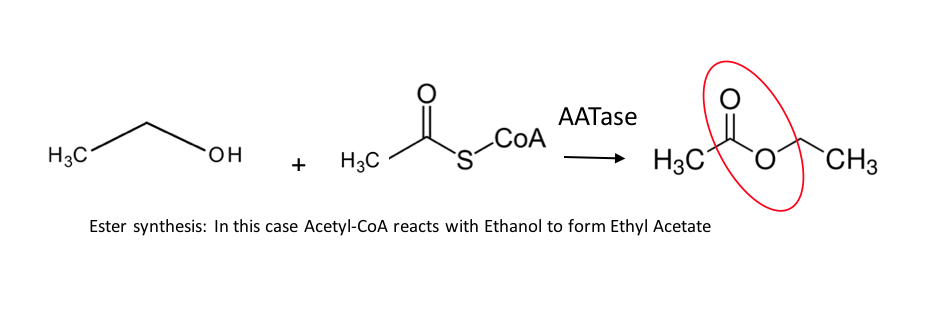

The classic Banana flavour, chemical name Iso-amyl acetate, in Wheat Beers comes from a group of chemicals called Esters. Volatile Esters are very flavour active and often form a significant proportion of the aroma profile in any beer. These volatile esters arise due to the enzyme catalysed reaction of an alcohol molecule with an Acetyl-CoA molecule.

The enzyme responsible for mediating the reaction is the alcohol acetyl transferase or AATase [6]. As these esters are soluble in the lipid based walls of yeast the smaller chain esters are able to leave the cell and contribute to the aroma profile of the beer [6].

Yeast metabolism and Ester synthesis is a complex process and certainly too broad a subject to be fully broached within the scope of this article. To simplify, essentially the production of Esters hinges on three variables. The concentration of the substrate Acetyl-CoA and alcohol molecules, and the concentration and activity level of the AATase enzyme, which catalyses the reaction [6]. The brewer can guide this process by manipulating the following variables.

Controlling Ester formation

Choice of yeast strain – The degree to which a particular yeast strain produces a specific Ester profile is greatly influenced by its genetic makeup. The possession and expression of genes encoding enzymes involved in Ester synthesis is strain dependent and will define the final Ester profile of the beer [7]. As with Phenols the best way forward here is to contact your yeast supplier and to ask for advice.

Temperature – Raising the temperature of fermentation increases the expression of enzymes related to the synthesis of Higher Alcohols in yeast cells as well as the aforementioned AAtases [7]. The result is increased Ester formation with one study noting a 75% increase in Ester formation between 10-12 degrees [7].

Hydrostatic pressure – Tall, and or, pressurized fermenters increase the concentration of CO2 dissolved in solution. High dissolved CO2 inhibits yeast growth by slowing decarboxylation reactions involved in the synthesis of Acetyl-CoA and Higher Alcohols [8]. The consequence is decreased Ester production at high hydrostatic or top pressures [8].

Wort Composition, Sugars, FAN, Oxygen and Fatty Acids – Unsurprisingly the composition of wort greatly influences the final Ester profile of a beer. Studies have shown that rising levels of Glucose in wort increases the final Ester concentration in a beer; although the mechanism behind this effect has still to be fully elucidated [9].

Increasing Free Amino Nitrogen or FAN increases the synthesis of Higher Alcohols leading to greater Ester formation [7]. Finally, higher levels of Oxygen and Fatty Acid are known to decrease levels of Ester synthesis by reducing the expression of genes controlling the AATase [7].

Conclusion

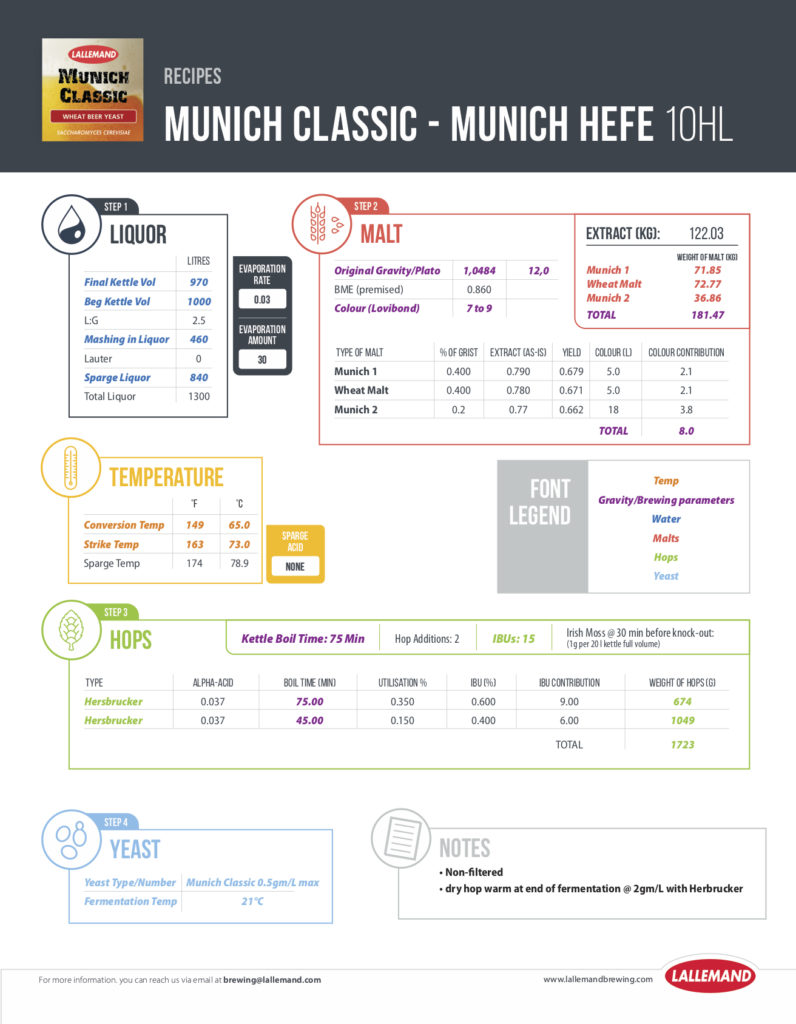

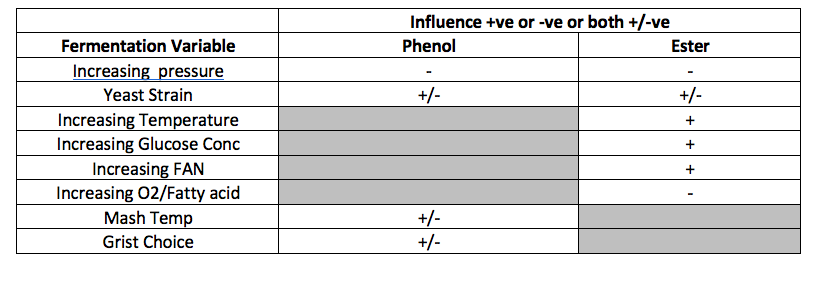

There are practical steps a brewer can take to influence the yeast derived Esters and Phenols present in Wheat Beer as well as in other beers. Please see the table below for a summary. To this end, the relationship with your yeast supplier is key. They will know how their strains perform and can make suggestions to brewers for their best use. Included on the following pages are an example recipe for a classic Weisse beer as well as information on our Munich Classic and Munich Wheat beer strains.