By investing in a new can filler Camerons Brewery, which offers a raft of services to the brewing industry, is now capable of achieving output speeds twice it could previously. This is how they did it.

Camerons Brewery carries out a wealth of contract brewing and kegging services for many international brewers and brands. Six years ago they added a contract bottling facility with equipment supplied by Enterprise Tondelli which enabled them to offer an integrated brewing and bottling service to their customers. In 2019, they added a contract canning line also from Enterprise Tondelli.

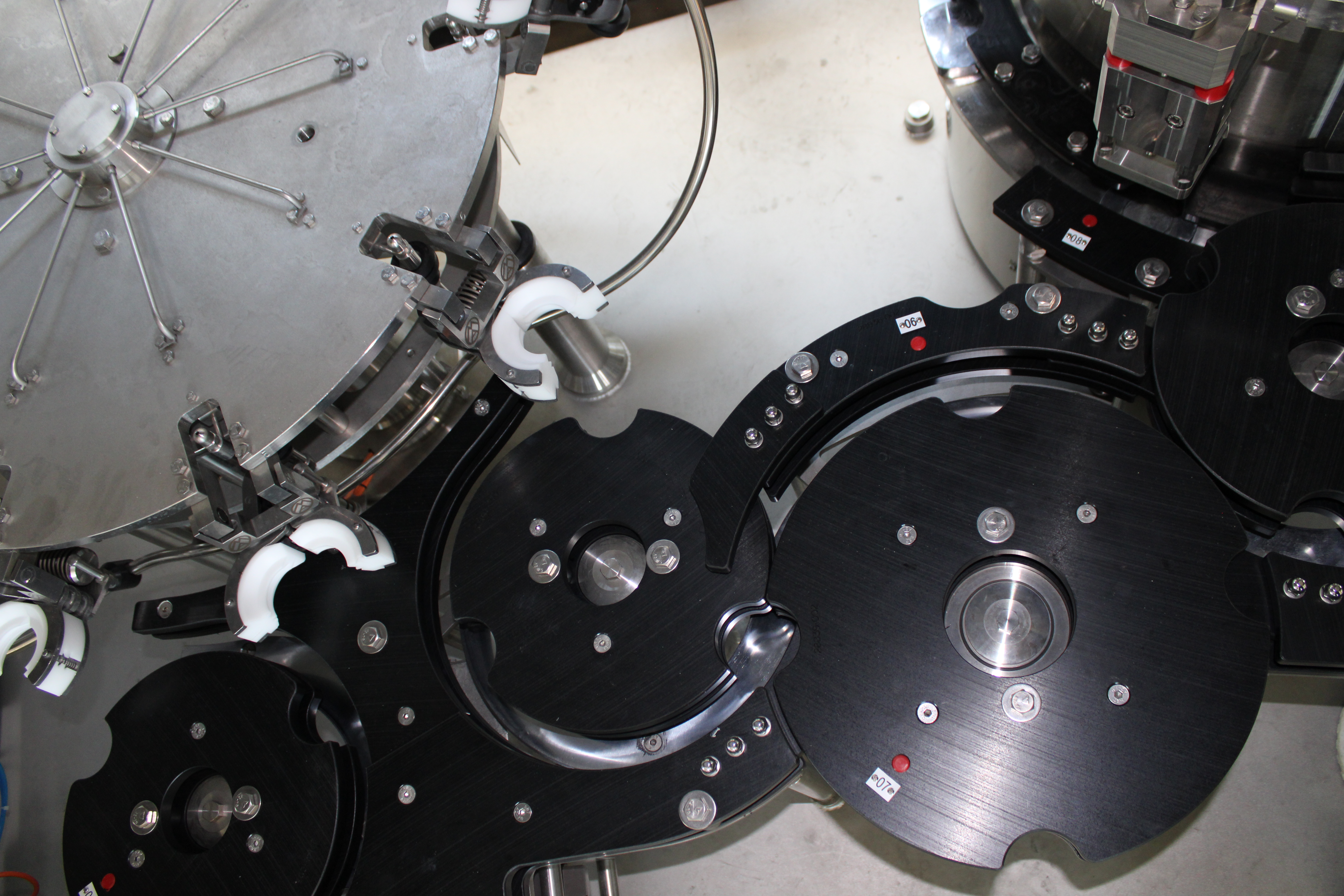

Now, Camerons Brewery has upgraded their canning facility with a faster can filler so the line output is now double the initial speed. The new filler, supplied by Enterprise Tondelli, from their manufacturing partners in Italy, Matrix Srl has features that make it world class. Incidentally the bottle filler was also manufactured by Matrix Srl.

Typically can fillers have an annular ring filler bowl which is difficult to clean. However, the new Matrix can filler has a central filler bowl with a CIP spray ball for enhanced cleaning. The cans are static so there are no can lifters with can turbulence and attendant maintenance requirements. Filling valves only move 5 mm to seal the can for flushing then filling. This means very little mechanical wear and tear and a much smoother can progress.

The filling system is using a well proven electro pneumatic control system that has been used by Matrix for a number of years now across both the bottle and can filler range. It significantly reduces maintenance, makes the filling operation more reliable and also much more controllable.

For instance the flushing cycle of the machine is recipe driven from the control panel along with the snifting cycles. This can be pre-set by the customer for all the different beers and the filling characteristics they may have. Snifting can be in multiple steps and varying times – all set from the operator panel.

Foam control is set from the panel and can be altered and saved for different beers such as nitrogenated releases. As the filling valves are recipe controlled it also means that should the filler bowl stop with cans on the carousel they will complete their total filling cycle even though the filler is static which stops overfills. The concept is to make the machine as operator friendly as possible so that it can be as flexible as possible without incurring costs for specialist programming engineers.

To reduce wastage and give a much more accurate fill volume, flow meters are fitted on every filling valve. Typically a fill accuracy of +/- 2ml is achieved. It also means that fill volumes can be adjusted from the control panel for the different cans sizes being handled.

There is a feedback loop to the operator panel so you can see the filling trend of each and every filling valve whilst running. The flow meters are available “off the shelf” as a proprietary component reducing the total cost of ownership. Using flow meters also gives very very low TIPO.

The constructional style of the machine is focused on hygiene with the filler bowl area exposed or “naked” so that external cleaning is very easy. Historically, manufacturers have fitted a cover but this often ends up hiding an unhygienic area so this bold step obviates that problem. It also means that maintenance is much easier as access is very open.

A separate valve skid makes connection to the machine for the services a very quick and easy operation. The skid includes the CIP return pump to ensure that cleaning is fully carried out at the correct flow rate. For an effective CIP the machine automatically cleans the filler product pathways, snifts etc with a 10 step sequence!

The filler has been in for some months now and has exceeded the customer expectations. Chris Deakin, brewing operations director at Camerons Brewery said: “ The new can filler has been an excellent upgrade to our canning line. Both the TIPO and also filling speed has exceeded contractual obligations. The machine has required very little input from ourselves and maintenance has been vastly improved.”

Another Matrix can filler recently supplied by Enterprise sported a rotary rinser as part of the can filler/seamer bloc. This is a concept first used by Enterprise in 2001 and it is especially suited where short stack cans are used.

The other advantage is that it guarantees jetting and draining times for greater product security as the rinsing nozzle follows the can on the carousel unlike a gravity can rinser where the rinse nozzle is static. For hygiene the unit is also fitted with hepa filtration and will be used for beer filling on sleek 330 ml cans. Change parts will allow the unit to fill carbonated soft drinks in 330 ml standard cans too.

Other new can fillers from Matrix include one for 36,000 cans per hour but able to fill carbonated soft drinks filling at 2-4 degrees C. along with fill hot filled juices with a volumetric filling valve. During the filling of juices at high temperature the filler does not recirculate the product. However should there be a stoppage then a recycling mini valve actually fitted on the filling valve bloc recirculates the product back to the flash pasteuriser for processing.

This ensures a temperature always of +/-1 degrees C. during the filling operation regardless of filler condition. Historically the recirculation valve on a carbonated filler would have been on the product inlet meaning a bowl full of product out of specification. Just another example of innovative solutions and quality available from Enterprise Tondelli and their manufacturing partners.