In his latest article, Tim O’Rourke, technical editor at The Brewers Journal, investigates warm maturation and cold stabilisation.

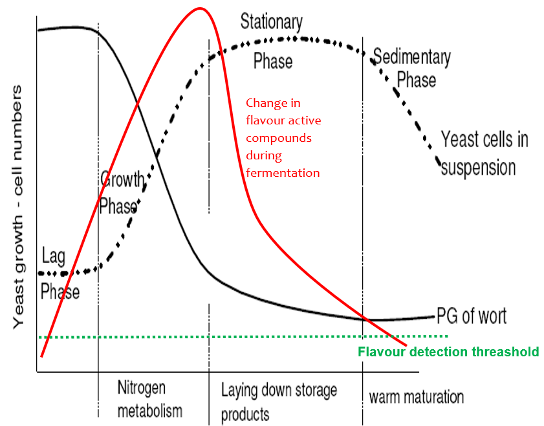

Warm maturation (secondary fermentation) occurs on the completion of primary fermentation when the growth (budding phase) is complete. As yeast transitions from growth to maturation yeast metabolism changes from producing the compounds necessary for budding and focuses on producing energy storage compounds such as glycogen and trehalose necessary for facing a period of starvation. The reactions involve flavour active compounds, associated with raw flavours, being reduced in order to recycle NADH to NAD.

The main flavour active compounds involved are:

➢Vicinal Diketones – 2,3 butanedione (commonly called Diacetyl) and 2,3 pentanedione. Diacetyl provides beer with unpleasant buttery, butterscotch flavours.

➢Aldehydes particularly acetaldehyde give beer a “raw green apple” taint.

Figure 1 shows the changes in flavour active compounds which increase during yeast growth (“overflow” metabolism) and falls as yeast reduces the compounds during the stationary phase.

These compounds are reabsorbed by yeast and reduced by NADH to produce less flavour active compounds as described in Article 4 and allowed to fall below flavour detection threshold.

Active live yeast in suspension is essential for the successful reduction of these unwanted volatile compounds which is affected by:

➢Time – longer stand times generally allow for greater reduction of unwanted volatile compounds; excessive time can result in poor yeast health with a gradual increase in raw flavour compounds being released particularly diacetyl.

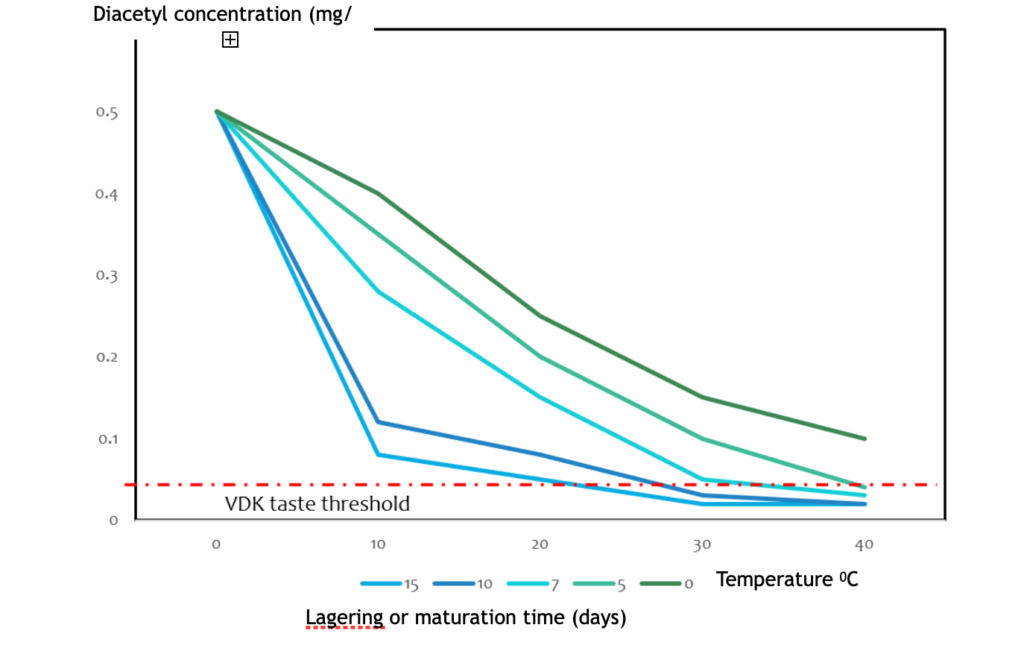

➢Temperature – the rate of diacetyl reduction in particular is accelerated at higher temperatures, but once achieved the beer should be cooled.

➢pH – lower pH improves the rate of redox reactions and favours wort acidification and vigorous fermentation.

Ales have warmer fermentation temperatures which accelerates the reduction of the raw flavours. Cask ales still have residual fermentable extract and viable yeast to allow conditioning in the cask either in a temperature regulated beer store in the brewery or the customer’s cellar.

Ales for keg and small pack are brewery conditioned with a warm diacetyl rest for 1 to 2 days before being cooled to between +2 and 00C for sedimentation, they can then be filtered and packaged (usually with some form of pasteurisation or sterile filtration) or packaged unfiltered which provides oxygen scavenging with some microbiological resistance. Ale yeast shows little growth below 60C and so there will be little metabolic change at low temperature.

Reducing diacetyl is more problematic in cooler lager fermentation where temperatures could be as low as 8 to 90C. Fermentation and maturation are usually treated as separate steps, but there is significant overlap between the two events.

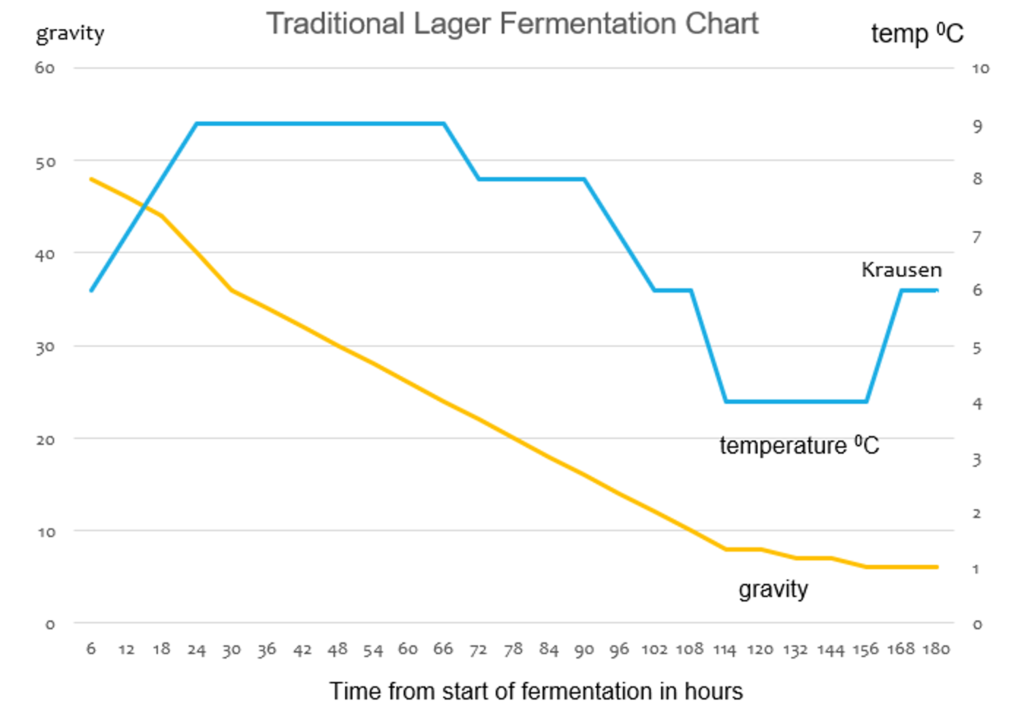

In figure 3, Wort is collected at around 60C with a fermentation time of between 7 and 10 days and a top temperature of 90C.

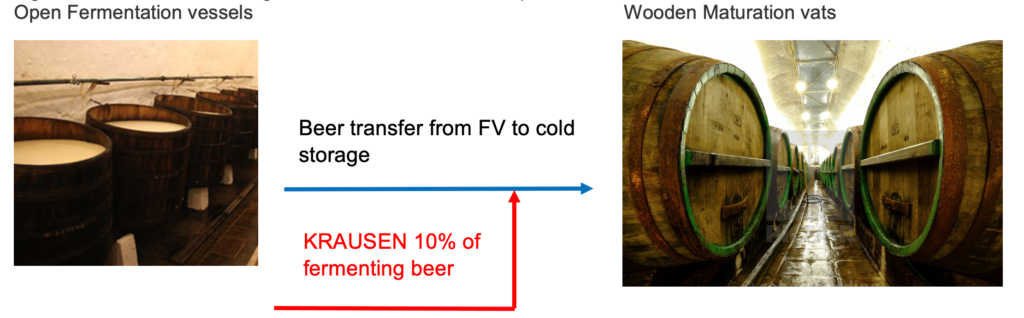

When fermentation is finished the beer is cooled to 40C to settle the yeast and the beer is transferred to the “warm maturation” barrels. 10% actively fermenting beer from a later fermentation is added as kräusen.

Kräusen adds live yeast and sugar to produce an active secondary fermentation.

Ø > Yeast scavenges any residual oxygen from the cask.

Ø > Yeast reduces residual diacetyl and acetaldehyde

> Secondary fermentation gives off CO2 which produces condition.

In 4A, traditional fermentations wort is collected at around 60C and allow to rise to 90C before being cooled through a series of steps to 40C to settle the yeast. The green beer is transferred to warm storage along with 10% actively fermenting beer at 90C for a secondary fermentation and is then slowly cooled over several weeks to 00C for sedimentation and stabilisation.

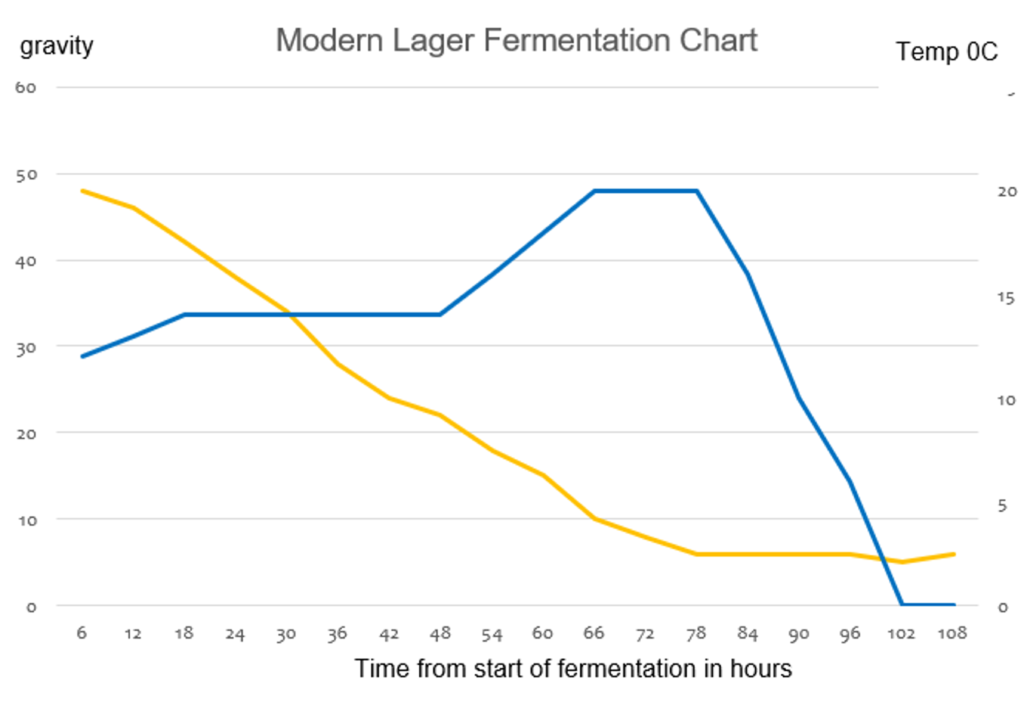

In 4B: Modern fermentation systems take advantage of improved equipment and a better understanding of warm maturation. The wort is collected between 10 and 120C and usually allowed a free rise to 13 to 140C. At 1/3 original gravity the temperture is allowed to free rise as high as 200C to complete diacetyl removal before being centrifuged and crash cooled to 00C for cold stabilisation.

In a traditional two-vessel process, lager beers are transferred following primary fermentation and cooling (to approximately 40C), into a separate vessel, where residual sugars (maltotriose and sometimes maltose) are slowly fermented. At the same time, off-flavours are reduced, and the beer becomes carbonated as the yeast continues to give off carbon dioxide.

Some breweries add kräusen, (a small proportion of fermenting beer), before the beer is transferred to a “Lagering” (cold storage) vessel. The introduction of active yeast during this process can help the beer mature more quickly and produce vigorous natural carbonation.

Figure 4a: Traditional lager fermentation profiles

Figure 4b: Modern lager fermentation profiles

Cold-fermented beers heighten “green” flavours production compared with beers produced using a higher fermentation temperature and requiring a longer period of warm and cold maturation referred to as “Lagering.”

With the introduction of rapid warm maturation processes, many brewers carry out fermentation and warm maturation in the same vessel, reducing times to 1 to 2 weeks, and the beer is centrifuged, and crash cooled for 2 days to 2 weeks cold stabilisation before filtration. The reduced process time has obvious appeal allowing lager beers to be produced in 2 to 4 weeks which requires fewer storage vessels.

In addition, there are rapid maturation methods available:

Passing warmed beer through an immobilised column of yeast to remove diacetyl

Adding an enzyme (alpha aceto-lactase decarboxylase) which converts alpha aceto-lactase to acetoin avoiding the production of diacetyl.

The original reason for the “Lagering” of beers in Germany was due to regulations restricting brewing to the winter months (between Michaelmas and St George’s day) which required the cold storage of beer to meet consumers requirement in the summer. Some traditional brewers continue to mature lagers between 4 – 00C for several months in the belief that it provides a smoother fuller taste and mouthfeel.

Most larger commercial brewers dispute this difference and (Metrulasas [2]) at UC Davis could not find any changes in the chemical composition of beers after prolonged cold storage and concluded that extended cold storage had no effect on flavour development.

In contrast Charles Masschelein [1] observed flavour improved in stored lagers which he attributed to non-volatile compounds from yeast, probably polypeptides. Murray [3] also noted fuller mouthfeel in stored beer with an increase tripeptides such as gamma-Glu-Val-Gly & gamma-Glu-Cys-Gly associated with Kokumi activity in food by activating calcium receptors on the tongue to en-hance flavour and mouthfeel. The effect is increased by CO2 top pressure to produce “harmonious palatability” in beer.

Eric Toft’s Brewmaster at Private Landbrauerei Schönramer [4] in his podcasts describes how 28 to 35 days storage is required to provide a mellow more balanced flavours which starts to be lost after 40 days. This greatly depends on alcohol strength with stronger beers benefiting from longer storage.

The same principles of longer storage benefits higher gravity ales. Since there will be little yeast metabolic activity it supports the observations of Masschelein and Murray that it is likely to be due to polypeptides leaking from aged yeast cells. Eric also considered there may be an increase in mellow esters. Extended storage with elevated temperatures results in yeast autolysis which contribute a meaty marmite flavour to the beer.

These observations are endorsed by Richard Keen of Cotswold Brewery [5] which follows a gentle cold conditioning programme for his lager after warm maturation, gradually cooling the beer to 70 then 50 and then 30 before storing at 00C for at least 5 weeks. A blind taste trial for standard lager beer (4% abv) after 2 and 5 weeks of cold storage showed a slightly smoother, subtle mellowness not present in the younger beer and with a noticeable increase is salivation in the mouth to create a better-balanced finished beer.

The maturation or lagering is more than just removing haze forming particulates or reducing off-flavours. The necessary amount of lagering time and the cooling protocols should be constructed to optimise the merging and integration of the desirable flavours and aromas to ensure a smooth blend of characteristics. This process should be carried out thoughtfully in preference to rapidly crash cooling which can result in “spikes” of flavour instead of producing well matured and well-integrated flavours & aromas.

Whether extended cold storage is a relic from the original Germanic brewing laws or a genuine improvement in drinkability still remains a matter of opinion.

Warm maturation is followed by a period of cold stabilisation at between 0 and -20C with lower temperatures being preferred. Little or no yeast metabolic activity occurs at these low tempera-ture and the focus is on clarifying and stabilising the beer:

- Flocculation and sedimentation of yeast is required to produce brighter beer and is a pre-requisite for beer filtration. It is essential to keep the beer cold to avoid autolysis with regular yeast purging.

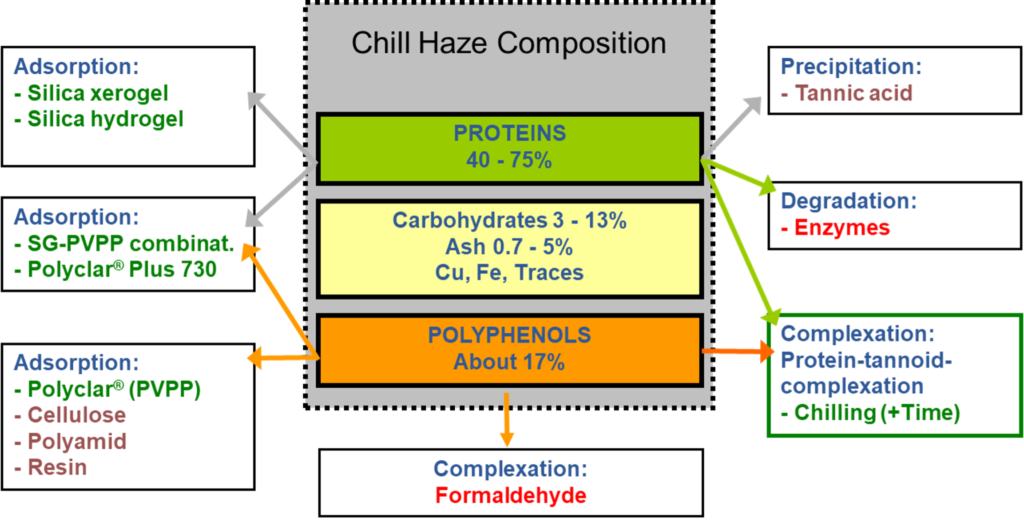

- Formation of chill and permanent haze due to the interaction between proteins and polypeptides in the beer with complex polyphenols which can be removed by settling or filtration is required for haze free beer shelf life.

The extent to which a beer requires haze stability depends on its required shelf life and storage conditions after packaging. For beers requiring a longer shelf life, such as small pack beers, then additional physical stabilisation is required.

Polyphenols (flavonoids) in the packaged beer can be oxidized to form larger chained tannoids, which react with protein molecules to initially produce chill haze and under more extreme circum-stances produce a haze which persists into the warm beer and is permanent haze.

The first manifestation of the loss of colloidal stability is observed as chill haze, which is a reversible association between small low polymerised polyphenols and proteinaceous material. The tendency to form chill haze progressively increases over time.

Oxidation of some polyphenols – flavonoids in particular, lead to the formation of condensed (polymerised) products. These are active precursors in haze formation, leading to permanent (irreversible) haze formation

Oxygen catalyses the polymerisation of simple flavonoids which become three to four units long, and which are able to bond with a number of proteins via hydrogen bonds to form chill haze

As the polyphenols continue to oxidise larger complexes are formed, and some of the polyphenol/protein hydrogen bonds are replaced by more permanent ionic bonds. These bonds no longer break when the beer is heated and leads to the formation of permanent haze.

To avoid colloidal haze production the brewer has to control brewing by the selection of brewing materials and production and storage of packaged beer. These steps can be divided into:

As the polyphenols continue to oxidise larger complexes are formed, and some of the polyphenol/protein hydrogen bonds are replaced by more permanent ionic bonds. These bonds no longer break when the beer is heated and leads to the formation of permanent haze.

To avoid colloidal haze production the brewer has to control brewing by the selection of brewing materials and production and storage of packaged beer. These steps can be divided into:

- Controlling the protein content of the beer

- Controlling the polyphenol content in the beer

- Controlling the physical conditions in the brewing process

Process aids can be added to reduce proteins or polyphenols.

By optimising the brewing process, it is possible to produce beers which are stable for up to 3 months without additional treatment. However, if a longer shelf life is required chemical stabilisers are recommended.

Citations & Further Reading

1. Charles Masschelein “Biochemistry of Maturation” Journal of the Institute of Brewing Volume 92 1986

2. Laura K. Metrulas, Christopher McNeil, Carolyn M. Slupsky, Charles W. Bamforth “The application of metabolomics to ascertain the significance of prolonged maturation in the production of lager-style beers” Journal of the Institute of Brewing Volume 125 2019

3. James Murray “Beer maturation: lessons from the past … and some” Brauwelt International 2020

4. Eric Toft – https://www.youtube.com/watch?v=PIHfZ60MJwM & https://player.fm/series/craft-beer-brewing-magazine-podcast/ep-244-eric-toft-of-schonramer-is-fixated-on-consistency-drinkability-and-character

5. Richard Keene founder and Head Brewer of Cotswold Brewing Company personal communication.

6. Tim O’Rourke “The mechanism of colloidal instability in beer and its consequences for haze and flavour stability” Ferment vol 11 No 3 1998