In his previous articles, (yeast carbohydrate metabolism & yeast flavour development) The Brewers Journal’s technical editor Tim O’Rourke looked at yeast metabolism and biochemistry during yeast growth. In this piece, he focuses at the mechanism of yeast growth and its behaviour during fermentation.

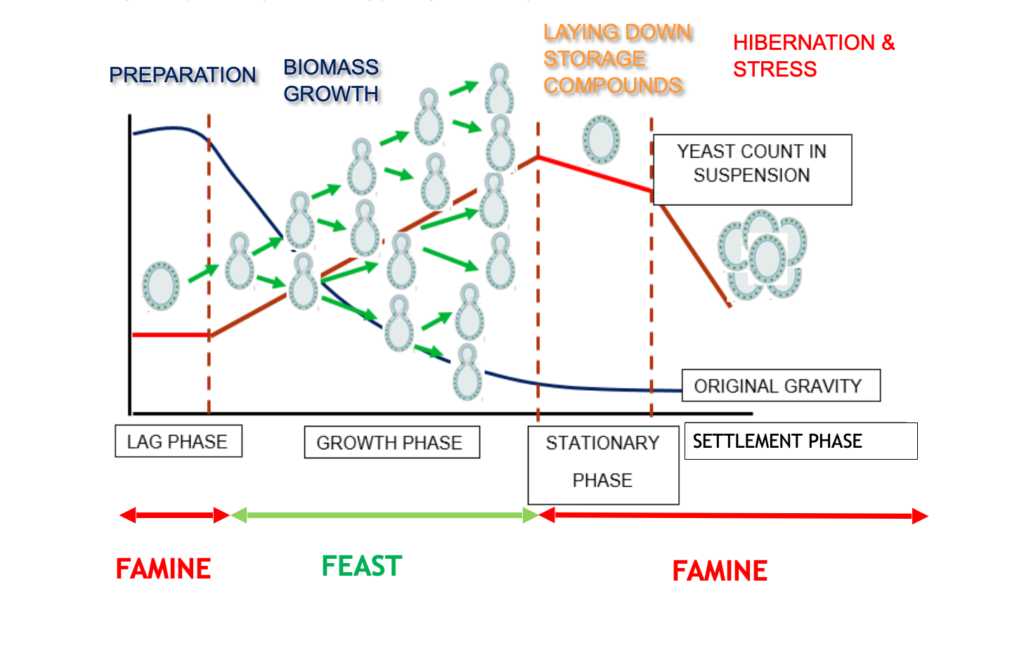

Yeast evolved along with flowering plants to utilise the sugars produced by fruiting bodies and adapted to times of bounty during fruiting in the autumn and times of shortage between the fruiting seasons. Brewing yeast experiences a similar cycle of feast and famine.

Lag phase

Yeast starts from a condition of famine when it is pitched into wort and requires a short time to acclimatise and take up certain essential nutrients such as amino acids and oxygen before it can start to grow.

Growth phase

Yeast enjoys a nutrient rich sugar environment, brewers’ wort, exploding into growth taking advantage of the feast to convert sugars into alcohol and carbon dioxide releasing the energy necessary for asexual reproduction (budding). Yeast multiplies by 4 to 6 times with a typical lager pitching rate 8 – 10 x 106 cells per ml to give a final yeast count of 50 to 60 x 106 cells at the end of the fermentation stage.

Stationary phase

As fermentation proceeds the sugars are used up (as shown by the fall in gravity/ density) and conditions become unfavourable for growth with a buildup of alcohol and carbon dioxide and a fall in pH. Yeast cells stop reproducing and start to prepare for the next stage of famine by laying down energy storage compounds such as glycogen and compounds to protect the cell against stress such as trehalose and ergosterol. This is the Warm Maturation stage with the reduction of some flavour active compounds such as diacetyl and acetaldehyde.

Settlement phase

With the completion of fermentation, yeast reduces it’s metabolism to virtually nothing to save energy and many yeast strains clump together (flocculate) and settle out. From this stage until it is re-pitched into fresh wort the yeast is experiencing famine putting cells under severe stress with a loss of viability and vitality.

Designing systems for top cropping ale yeast

Brewers have designed their fermentation systems around yeast behaviour. Traditional methods of fermentation grew up around the technology and materials available at the time and are adapted to the behaviour of the yeast and the nature and dispense characteristics of the beer.

The first beers were probably fermented in clay or wooden vessels using wild yeast and bacteria from the environment. As volumes increased the use of pitching or “back slopping”, where the foam off a recently fermented beer is added to a fresh brew, was used to improve fermentation performance. Beer quality was also improved by better solid separation to produce a cleaner brighter beer.

Before refrigeration brewers had to rely on natural temperature to cool the wort. This was usually done in a large shallow open vessel called a “coolship” where the wort was cooled by natural cool air flow over night.

Part of the brewing process involves clarification by removing solid material and insoluble proteins called “cold break”, which settle out and is left behind at the end of wort transfer.

As the wort cools down it will absorb air (oxygen) from the atmosphere which is necessary for yeast growth.

Collection vessel

The cool wort (circa 170C) is dropped into an un-attemperated vessel with pitched yeast. As the fermentation starts the yeast grows and temperature increases to around 200C (taking around 20 – 28 hours). It is then “dropped” into the attemperated fermentation vessel below leaving some cold break behind.

Second fermentation vessel

Dropping adds more oxygen and improves yeast dispersal. Attemperation coil maintains fermentation temperatures at 200C. The sluice gate shown in black allows collection of the top cropping yeast ready for a subsequent brew.

Traditional beers (ales and lagers) were all unpasteurised and unfiltered, requiring the yeast count in suspension to fall from around 60 x 106 cells per millilitre at the peak of fermentation to 1 x 106 cells per millilitre necessary for conditioning (secondary fermentation). A lot of yeast settles due to flocculation and a decrease in temperature from 220 to 80C, However, special secondary fermentation vessels were developed designed to separate the yeast from the fermented beer controlling the yeast count and supplying a clean accessible source of yeast for re-pitching.

Fermenting wort is collected in a set of linked attemperated 5-barrel barrels where the yeast is allowed to rise up through the swan necks and is collected and cooled in the top trough leaving beer with the correct yeast count for racking in the barrels.

The beer ferments in the attemperated lower chamber and the yeast rises up the central port where it is retained on the shelf and can be run off for re-pitching and leaves beer with the correct yeast count for racking in the bottom chamber.

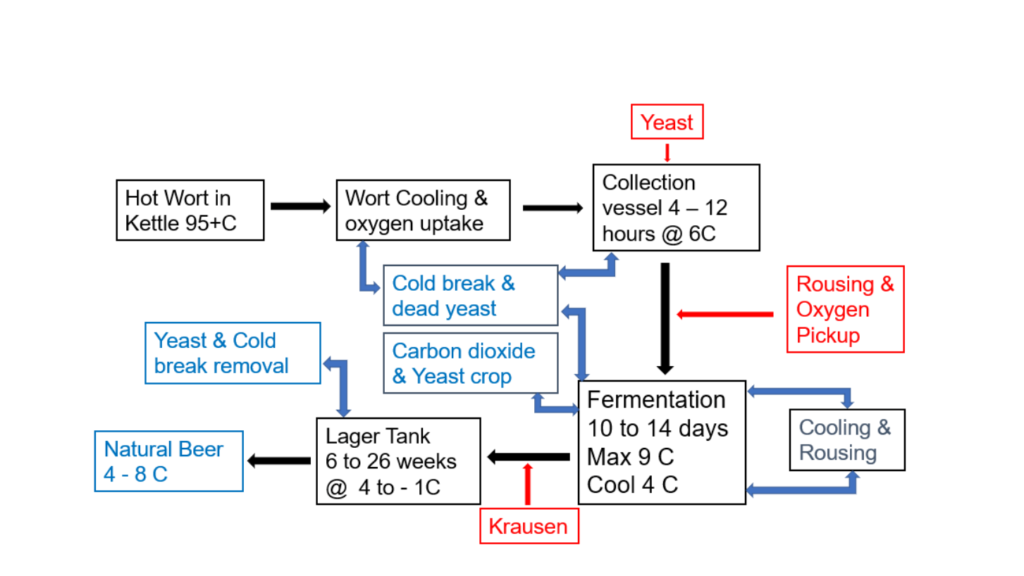

Designing Systems for bottom cropping Lager yeast

Originally beers produced throughout Europe were ale style beers using top cropping saccharomyces cerevisiae. This continued until William IV of Bavaria passed the Reinheitsgebot regulations in 1516 limiting brewing ingredients which was later extended to restrict dates during which beer could be brewed to between Michaelmas (the feast of Saint Michael and All Angels on the 29th September) and Georgi (St Georges day 23rd April) which meant that fermentation occurred at low winter temperatures not conducive to ale yeast growth. This resulted in a new species evolving through the hybridization of Saccharomyces cerevisiae and Saccharomyces eubayanus to produce a new bottom cropping strain of lager yeast Saccharomyces pastorianus which was adapted to growing at lower temperatures.

However, the basic brewing process remained largely the same with the lower fermentation temperatures extending fermentation times and the lower times and temperatures stressed the bottom cropping Lager yeast which remains in the vessel until fermentation is completed. Ale yeast can be skimmed from the top of the vessel as required allowing improvements in yeast health.

The other issue facing Bavarian Brewers was logistics, supplying the market with beer during the summer from beer only brewed in the winter. To overcome this Brewers, produce a new style, Lager (stored beer) which was kept in cool cellars to meet sales demand with a sale at the end of the summer, Octoberfest, to empty the vats ready for the next year’s production.

Many of the same considerations apply to lager brewing with the need to aerate the wort and the removal of unwanted solids and proteins. However, the cooler conditions and the longer fermentation times affected the viability of the yeast required to provide a secondary fermentation during warm maturation/cold storage which for traditional lagers occur at 4 – 60C. To ensure good condition of the lager yeast a process of “Krausen” is used where actively fermenting wort (containing budding yeast and fermentable sugars) are added to the maturation vessel to build up dissolved carbon dioxide, the yeast will also help to scavenge any oxygen from the container and reduce diacetyl.

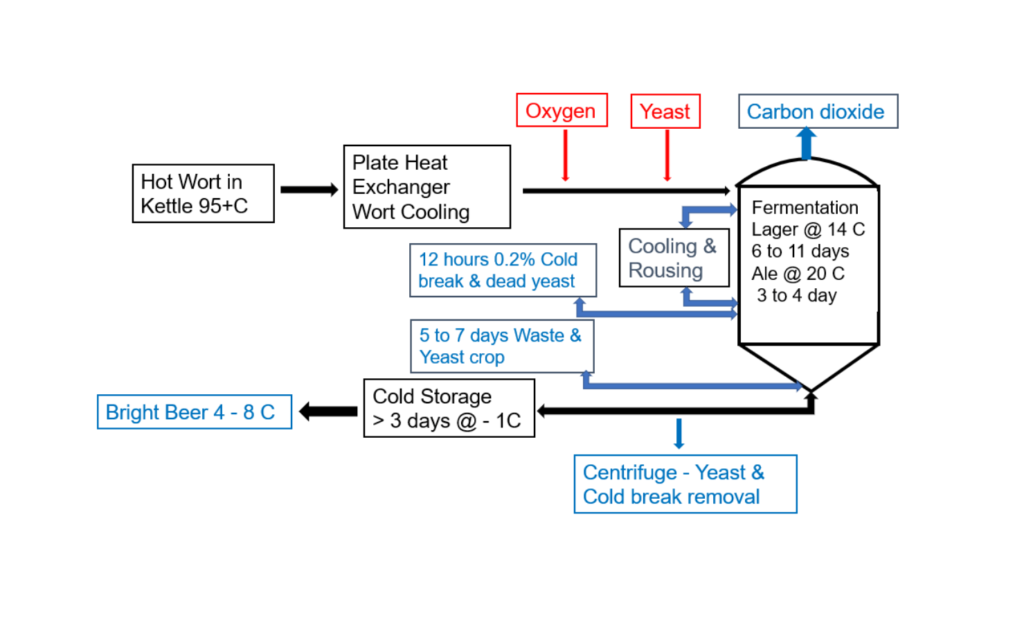

Modern Conical Systems for all beer styles

Developments have allowed the fermentation process to be updated and most importantly speeded up, and modern conical fermenters can be used for both Ale and Lager fermenting.

The new modern cylindro conical vessel has generally superseded the traditional fermentation vessels but the same operations and constraints still apply, only this time it is simpler because of the benefits of improved technology.

The modern whirlpool is far more efficient for trub removal reducing the carryover of cold break, however best industry practice still expects a small amount of wort to be removed from the cone between 12 and 24 hours after collection to remove cold break and dead yeast cells.

Modern aeration systems and cooling systems ensure good control is achieved and with the yeast pitched in line there is thorough yeast mixing. Additional rousing and aeration can be achieved in the vessel, and it is fully cleanable and sterilisable.

Ale yeast crop at the top of shallow traditional fermentation vessels because of its affinity to attach to gas (CO2) bubbles, a similar affinity is not present in lager yeasts which sink to the bottom. Because of the wort depth (hydrostatic pressure) the CO2 gas bubbles which carry the ale yeast to the top of the vessel dissolve and cease to support the yeast which settles to the bottom of the vessel under gravity. Since the pitching crop is also collected from the cone there is an additional selection pressure in favour of bottom cropping yeast.

Specification

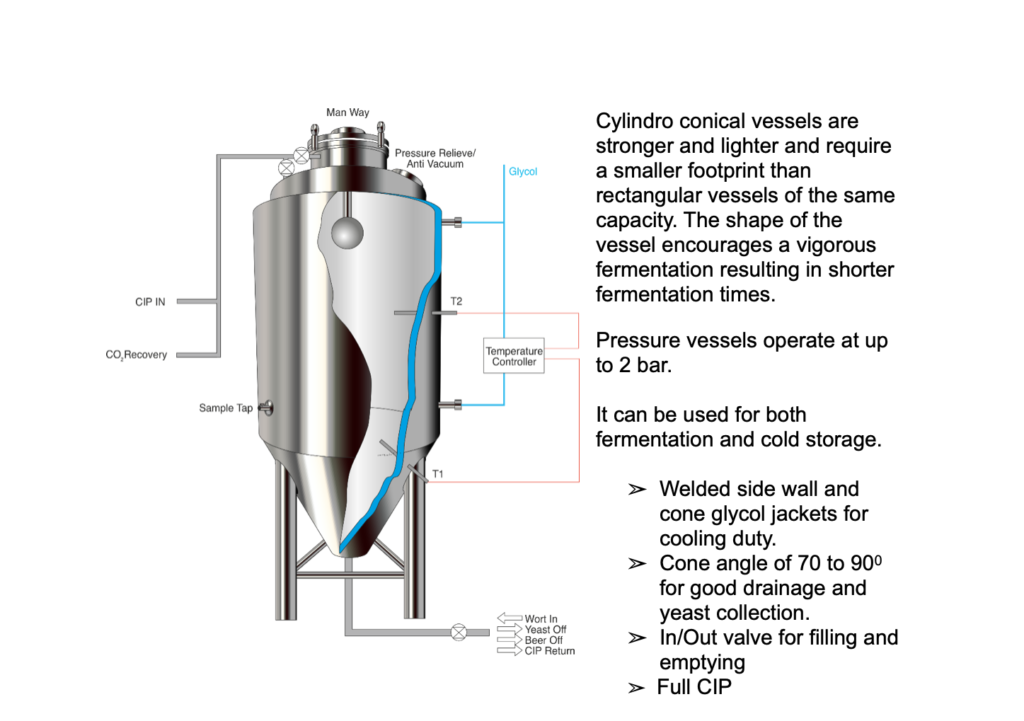

Cylindro conical vessels are stronger and lighter and require a smaller footprint than rectangular vessels of the same capacity. The shape of the vessel encourages a vigorous fermentation resulting in shorter fermentation times. Pressure vessels operate at up to 2 bar.

It can be used for both fermentation and cold storage.

- Welded side wall and cone glycol jackets for cooling duty.

- Cone angle of 70 to 900 for good drainage and yeast collection.

- In/Out valve for filling and emptying

- Full CIP

The cone helps concentrate the yeast which results in more dense yeast cone resulting in lower beer wastage/losses. In this vessel yeast is removed first before pumping the beer. Cone cooling ensure the yeast is maintained in good temperature condition. Cooling is achieved by wall and cone jackets and in a regular fermentation the major cooling effect is achieved by the top jackets as the warmer beer rises and as it is cooled it will fall to the cone. This action is greatly increased when the yeast gives off CO2 which also helps to stir the fermenting vessel during active growth.

CO2 bubbles generated during fermentation cause strong circulation currents. This ensures consistent yeast concentration throughout the wort and improves the growth rate of yeast. It also gives more effective cooling as the wort passes over the cooling surfaces.

The conical fermenter is ideal for bottom cropping yeast. The cone makes it easy to collect yeast. There is also a small, but significant saving in the “loss” of bittering materials by yeast adsorption with bottom settling yeasts.

The totally enclosed design makes it easy to incorporate in place cleaning using either a spray balls or high-pressure cleaning heads. However, enclosure also makes it necessary to incorporate pressure and vacuum relief devices. These are essential to prevent explosion or collapse. The design of the vessel, the quantity of CO2 remaining after emptying, and the type of cleaning reagents and temperatures used for cleaning must all be considered when preparing a cleaning regime.

CO2 from the fermentation can easily be collected with minimal wastage of impure gas due to the effective headspace purging.

Thermometers are required at different heights, to accommodate the different density of wort / beer at different temperatures. During fermentation, convection currents are created in the FV, with the wort in contact with the cooling panels becoming denser, and falling, with the warmer beer in the centre rising with the coldest wort towards the bottom of the vessel.

The temperature probe therefore measures wort at its coldest and will stop cooling if below the temperature set-point. At the end of fermentation, when cooling to less than 4oC, when the beer is colder than 3.5oC, the density decreases, and the cold beer rises to the top of the vessel alongside the cooling jackets, and back down the center of the FV. A high-level probe is therefore required to prevent ice formation at the top of the vessel.

As well as relying on yeast flocculation and cooling to separate the yeast at the end of fermentation a centrifuge can be used to remove almost all the yeast before cold stabilisation further reducing vessel occupancy.

Fermentation summary

Yeast added to the cold wort collected from the brewhouse converts sugars to ethyl alcohol (ethanol). Yeast also produces a number of minor fermentation by-products which contribute greatly to beer flavour.

Fermentation is controlled by:

- Nutrient status of wort

- Number, type & health of yeast

- Temperature – collection & top temperature

- Time duration of fermentation